Why Is FRP Flat Plate a Game Changer in Construction and Industrial Applications?

2024-11-14

In the world of construction and industrial applications, choosing the right materials is key to ensuring durability, cost-efficiency, and performance. One such material that has been gaining significant attention is the FRP flat plate (Fiberglass Reinforced Plastic). But why exactly should you consider FRP flat plates for your next project? What makes this composite material a game changer in construction, infrastructure, and industrial settings? In this blog, we’ll dive into the benefits and applications of FRP flat plates and explore why they are increasingly being seen as a top choice for modern-day construction and engineering projects.

What Is an FRP Flat Plate?

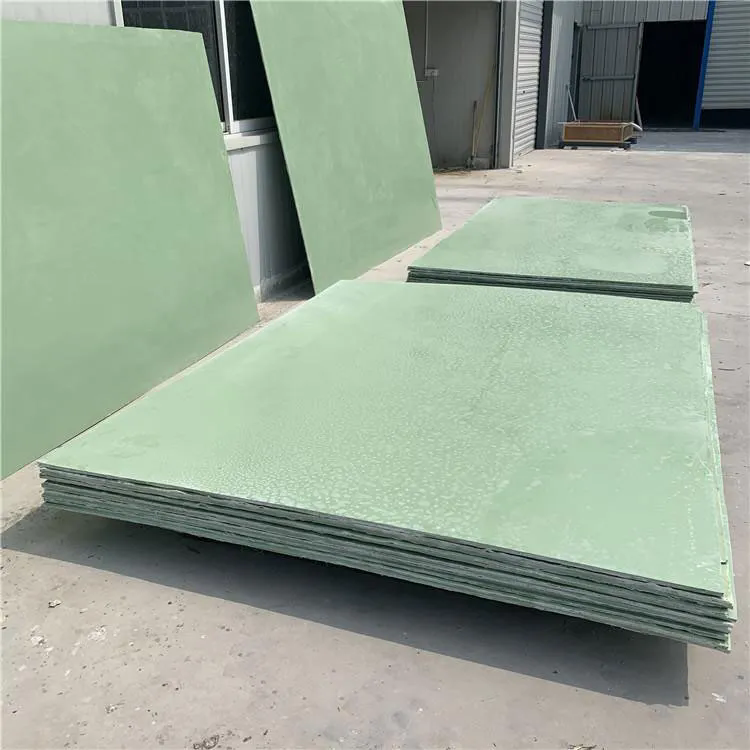

An FRP flat plate is a type of composite material made from fiberglass and plastic. The plate consists of a reinforced fiberglass layer combined with a matrix of durable plastic resin. The result is a highly strong, lightweight, and corrosion-resistant material that is used in a wide range of applications. The flat plate design typically features a smooth surface and is available in various sizes, thicknesses, and finishes to meet different project requirements.

FRP flat plates are commonly manufactured through processes like hand lay-up, pultrusion, or filament winding, depending on the specific strength and performance requirements of the application. They can be customized to offer chemical resistance, flame retardancy, and UV protection, making them ideal for specialized industries.

Why Choose FRP Flat Plates?

1. Superior Strength-to-Weight Ratio

One of the standout features of FRP flat plates is their excellent strength-to-weight ratio. These plates offer the strength of metal but at a fraction of the weight. This makes them much easier to handle, transport, and install, especially in applications where weight is a critical factor. The lightweight nature of FRP flat plates reduces the overall load on structural frameworks, which is especially important in industries like construction, transportation, and aerospace.

2. Corrosion Resistance

Traditional materials like steel and aluminum are susceptible to rust and corrosion, especially in harsh environments exposed to moisture, chemicals, or extreme weather. FRP flat plates, on the other hand, are highly resistant to corrosion and do not degrade when exposed to water, chemicals, or saline environments. This makes them ideal for use in industries such as marine, chemical processing, oil and gas, and wastewater treatment, where materials are often subjected to corrosive conditions.

3. Durability and Longevity

FRP flat plates are built to last. Their resilient construction allows them to withstand harsh conditions, including extreme temperatures, UV radiation, and physical stress. Unlike traditional materials that may weaken or degrade over time, FRP plates maintain their structural integrity for years without requiring frequent maintenance or replacements. This durability makes them an excellent investment for long-term projects and infrastructures.

4. Low Maintenance

Another significant advantage of FRP flat plates is their low maintenance requirements. Unlike metals that may need regular coatings, treatments, or inspections to maintain their condition, FRP plates are virtually maintenance-free. Their resistance to rust, UV degradation, and chemical corrosion means they require minimal upkeep, which can save both time and money over the course of the project’s lifecycle.

5. Fire Resistance

In some applications, fire resistance is a critical requirement. FRP flat plates can be designed with flame-retardant properties, making them an ideal choice for industries where safety is a concern. Whether in buildings, public infrastructure, or transportation systems, FRP plates can help reduce the risk of fire hazards, providing an added layer of protection to structures.

6. Design Flexibility

FRP flat plates can be easily molded or shaped into a variety of forms, allowing for greater design flexibility. Whether you need curved, rigid, or reinforced plates, FRP can be tailored to fit your specific needs. This adaptability makes them a popular choice for complex architectural designs, custom engineering solutions, or products that require specific dimensional characteristics.

7. Environmental Friendliness

As industries and companies move toward more eco-friendly solutions, FRP flat plates stand out as an environmentally conscious material. Fiberglass is recyclable, and the production process for FRP materials generally has a lower environmental impact compared to metal production. Additionally, their longevity and resistance to corrosion mean that FRP plates contribute less to the need for replacements and repairs, reducing the overall environmental footprint of a project.

8. Cost-Effective Solution

While FRP flat plates can be more expensive upfront compared to traditional materials, their long-term cost-effectiveness is undeniable. With lower maintenance costs, longer lifespans, and fewer replacements, FRP plates can save businesses and contractors money in the long run. Additionally, their light weight reduces transportation and installation costs, making them a cost-efficient option overall.

Common Applications of FRP Flat Plates

FRP flat plates are used in a wide variety of industries and applications due to their unique properties. Here are just a few of the common uses:

- Construction and Infrastructure: FRP flat plates are often used in building facades, roofing, and flooring due to their durability and resistance to the elements. They are also used for bridge decking, walkways, and structural reinforcements.

- Marine and Offshore: FRP is widely used in shipbuilding and offshore oil platforms. The material’s resistance to corrosion from seawater and chemicals makes it ideal for marine environments where other materials would degrade quickly.

- Chemical Processing and Storage: FRP flat plates are commonly used for chemical tanks, pipes, and vessels. Their chemical resistance and strength make them suitable for handling corrosive substances in industrial environments.

- Transportation: In automotive, aerospace, and railway industries, FRP flat plates are used for interior panels, insulation, and lightweight structural components. Their strength and low weight contribute to improved fuel efficiency and safety.

- Wastewater Treatment: The corrosion resistance and non-porous nature of FRP make it ideal for use in wastewater treatment plants, where they are used for tanks, pipes, and filtration systems.

Conclusion

FRP flat plates are quickly becoming one of the most sought-after materials for a wide range of industries, and for good reason. Their superior strength-to-weight ratio, corrosion resistance, low maintenance needs, and long-lasting durability make them an excellent choice for both structural and functional applications. Whether you're involved in construction, marine engineering, chemical processing, or another industry, FRP flat plates offer a reliable, cost-effective, and environmentally friendly alternative to traditional materials like metal and concrete.

So, if you're looking for a material that combines performance, longevity, and versatility, an FRP flat plate might be just what you need. Their unique properties make them a game-changer in the world of modern engineering and construction, offering a smarter, more efficient solution for a wide range of applications.