Why Are Self-Tapping Screws Essential for Your Next Project?

2024-11-05

If you've ever tackled a construction, DIY, or repair project, you may have encountered self-tapping screws. But what makes them such an invaluable tool in various applications? In this blog, we’ll explore why self-tapping screws are essential, the benefits they offer, and how to make the most of them in your next project.

1. What Are Self-Tapping Screws?

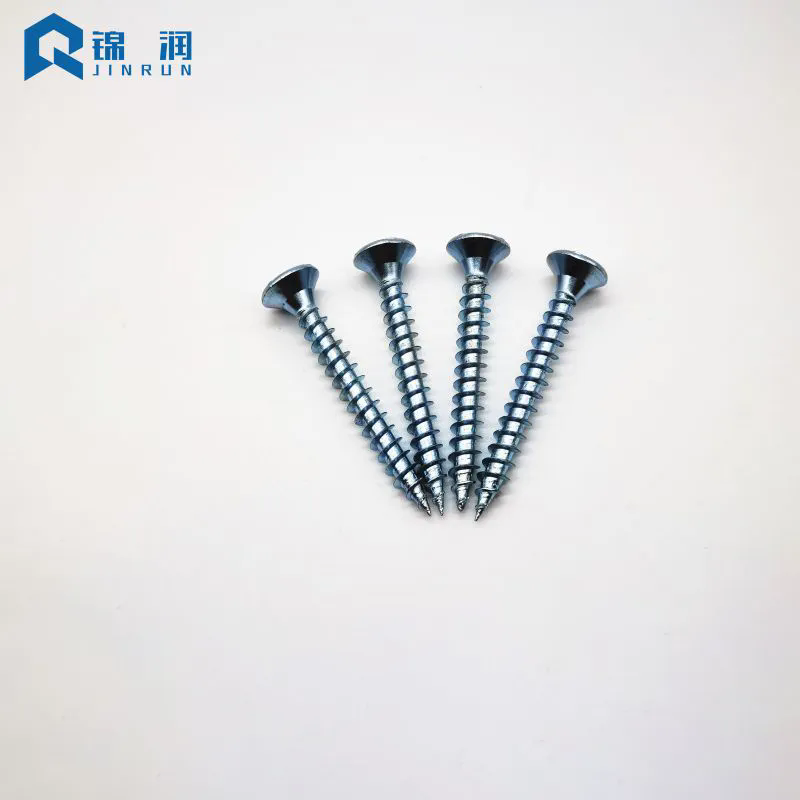

Self-tapping screws are fasteners designed to create their own threads as they’re driven into a material. Unlike standard screws, which require pre-drilled holes, self-tapping screws cut or form threads directly as they’re inserted. Available in a range of sizes, shapes, and materials, they are used in applications that need secure and durable fastening, especially in materials like metal, plastic, and wood.

2. How Do Self-Tapping Screws Improve Efficiency?

One of the biggest benefits of self-tapping screws is their time-saving quality. Since they don’t require pre-threaded holes, they eliminate the need for separate tapping, reducing the number of tools and steps needed. This simplicity speeds up assembly and installation, especially on large projects, and makes them ideal for fast-paced environments or jobs where precision and efficiency are a must.

3. Where Can You Use Self-Tapping Screws?

Self-tapping screws are incredibly versatile. They are commonly used in metalworking, woodworking, plastic assembly, and various construction projects. Their ability to cut into materials without causing splitting or cracking makes them useful for everything from assembling furniture to installing sheet metal, HVAC systems, and even automotive work. This wide range of applications means they can be your go-to screw for nearly any project.

4. Why Are Self-Tapping Screws Great for Durable Fastening?

Self-tapping screws create strong, lasting connections by forming threads that securely grip the material. This tight fit reduces the chances of loosening over time, making them ideal for applications that require durability, such as building structures or high-vibration environments like machinery. Their secure grip helps keep materials stable, which is crucial in both heavy-duty construction and precision tasks.

5. How Do Self-Tapping Screws Reduce the Risk of Material Damage?

When working with brittle or delicate materials, such as certain plastics or thin metals, pre-drilling can sometimes cause cracking, splitting, or damage. Self-tapping screws reduce this risk by forming threads gently and precisely, which minimizes stress on the material. This makes them particularly useful in applications where maintaining the integrity of the material is essential.

6. Are Self-Tapping Screws Cost-Effective?

Yes, they can be! Although they may have a slightly higher upfront cost than standard screws, self-tapping screws save you money in the long run. By eliminating the need for pre-drilling and tapping, they cut down on labor time and the need for additional tools, leading to cost savings on large-scale projects. Their durability and secure fastening also mean less frequent replacements, which adds to their overall cost-effectiveness.

7. Can Self-Tapping Screws Be Used for Repeated Assembly and Disassembly?

Self-tapping screws are particularly advantageous in applications that may require periodic disassembly and reassembly, as they provide a secure hold while being easy to remove and replace. This quality makes them ideal for situations where parts may need to be adjusted, serviced, or replaced, such as electronic enclosures, metal cases, and mechanical devices.

8. What Types of Self-Tapping Screws Are Available?

There are several types of self-tapping screws, each suited to different materials and applications. Common options include:

- Thread-Forming Screws: These are typically used for plastic, as they create threads without cutting, preventing cracking in softer materials.

- Thread-Cutting Screws: Often used for metal, these screws have sharper points to cut threads directly, providing a strong hold.

- Self-Drilling Screws: Also known as "TEK" screws, these have a drill-like point that can cut through thin metal without needing a pre-drilled hole, making them perfect for sheet metal work.

Selecting the right type of self-tapping screw based on the material ensures optimal performance and durability for your project.

Conclusion: Are Self-Tapping Screws Right for Your Project?

In summary, self-tapping screws offer a range of benefits, from saving time and improving durability to reducing material damage and costs. Whether you're working with metal, wood, plastic, or composite materials, self-tapping screws can provide an efficient, versatile, and secure fastening solution. So next time you’re planning a project, consider the advantages of self-tapping screws—they might just be the perfect tool to make your work easier and more effective!