Understanding Spray Quick-Insert Connectors: A Comprehensive Guide

2024-08-30

In the world of industrial and consumer applications, connectivity solutions are crucial for seamless operations. Among these solutions, the Spray Quick-Insert Connector stands out as a versatile and efficient choice for various applications. This blog will explore what Spray Quick-Insert Connectors are, their benefits, and their applications.

What is a Spray Quick-Insert Connector?

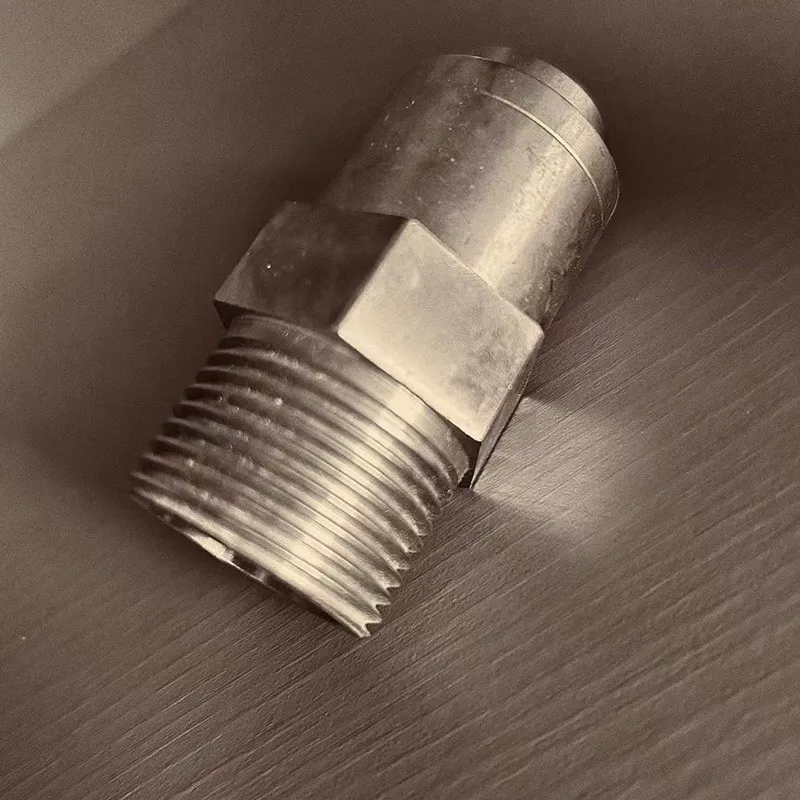

A Spray Quick-Insert Connector is a specialized type of connector designed to facilitate quick and easy connections between spray equipment and hoses or pipes. This connector is often used in industries where fluid transfer is a key component, such as in agriculture, automotive, and manufacturing.

The quick-insert design allows users to connect or disconnect the spray system with minimal effort, which is particularly useful in dynamic environments where speed and efficiency are paramount. These connectors typically feature a locking mechanism to ensure a secure and leak-free connection.

Benefits of Spray Quick-Insert Connectors

1. Ease of Use: The primary advantage of Spray Quick-Insert Connectors is their user-friendly design. The quick-connect feature eliminates the need for tools or complex procedures, allowing for faster setup and teardown.

2. Reduced Downtime: In industries where time is money, the ability to quickly connect and disconnect equipment can lead to significant reductions in downtime. This efficiency translates to increased productivity and lower operational costs.

3. Leak Prevention: Many Spray Quick-Insert Connectors are designed with built-in sealing mechanisms that prevent leaks. This feature is crucial for maintaining safety and efficiency, particularly when dealing with high-pressure sprays or corrosive fluids.

4. Durability: Made from robust materials like stainless steel or high-grade plastics, these connectors are built to withstand harsh environments and heavy usage. Their durability ensures a long service life and reliable performance.

5. Versatility: These connectors are available in various sizes and configurations, making them suitable for a wide range of applications. Whether you need a connector for a large industrial sprayer or a small handheld device, there is likely a Spray Quick-Insert Connector that fits your needs.

Applications of Spray Quick-Insert Connectors

1. Agriculture: In farming and horticulture, spray connectors are used in irrigation systems and pesticide applicators. Quick-connect features allow farmers to efficiently switch between different spray nozzles or equipment.

2. Automotive: In automotive maintenance and repair, these connectors are used in car wash systems, coolant systems, and other spray applications. Their quick-connect functionality helps streamline vehicle servicing.

3. Manufacturing: In manufacturing processes that involve spray painting, coating, or cleaning, Spray Quick-Insert Connectors facilitate easy transitions between different spray tools and equipment.

4. Food and Beverage: The food and beverage industry uses spray connectors in cleaning systems and automated processing equipment. The ease of connection and disconnection helps maintain hygiene standards and operational efficiency.

Conclusion

Spray Quick-Insert Connectors represent a significant advancement in connectivity technology, offering benefits like ease of use, reduced downtime, leak prevention, and versatility. Their applications span across various industries, demonstrating their importance in modern operations. Whether you're involved in agriculture, automotive, manufacturing, or food processing, incorporating Spray Quick-Insert Connectors into your setup can enhance efficiency and performance. As technology continues to evolve, these connectors will likely become even more integral to streamlined and effective fluid transfer solutions.