The Power of Para-Aramid Filament: Revolutionizing Strength and Durability

2024-08-10

Key Properties of Para-Aramid Filament

1. Exceptional Strength

- High Tensile Strength: Para-aramid filaments have a tensile strength significantly higher than steel. This makes them ideal for applications requiring materials that can withstand intense stress and strain without breaking.

- Lightweight: Despite their strength, para-aramid fibers are lightweight, which is crucial for applications where weight reduction is essential.

2. Heat and Flame Resistance

- Thermal Stability: Para-aramid fibers can withstand high temperatures without degrading. They maintain their properties even at temperatures as high as 400°C (752°F), making them suitable for applications exposed to extreme heat.

- Flame Retardant: The material is inherently flame-resistant, adding a layer of safety in environments where fire hazards are a concern.

3. Chemical Resistance

- Durability: Para-aramid filaments resist degradation from chemicals and solvents, making them suitable for use in harsh chemical environments.

- Longevity: The chemical resistance contributes to the overall durability and longevity of products made from para-aramid fibers.

4. Impact Resistance

- High Energy Absorption: Para-aramid fibers are designed to absorb and disperse impact energy, which is why they are used in protective gear and armor.

- Ballistic Protection: The material’s impact resistance makes it effective in providing ballistic protection in vests and shields.

Applications of Para-Aramid Filament

1. Aerospace and Defense

- Aircraft Components: In the aerospace industry, para-aramid filaments are used in the construction of aircraft components, including panels and structural reinforcements, due to their lightweight and high-strength properties.

- Military Gear: Para-aramid fibers are integral to military gear such as bulletproof vests, helmets, and body armor, offering protection against ballistic threats.

2. Automotive Industry

- High-Performance Tires: The strength and durability of para-aramid filaments are utilized in high-performance tires to enhance puncture resistance and stability.

- Reinforced Parts: The automotive industry uses para-aramid fibers in various reinforced components, including belts and hoses, to improve durability and performance.

3. Sports and Recreation

- Protective Equipment: Para-aramid fibers are used in protective sports gear, such as gloves, knee pads, and elbow pads, providing enhanced protection and durability.

- High-Performance Sports Equipment: The material is also employed in the construction of high-performance sports equipment like racing sails and bicycle frames, where strength and weight reduction are critical.

4. Industrial and Safety Applications

- Protective Clothing: Para-aramid filaments are used in industrial protective clothing, including fire-resistant suits and gloves, due to their heat and flame resistance.

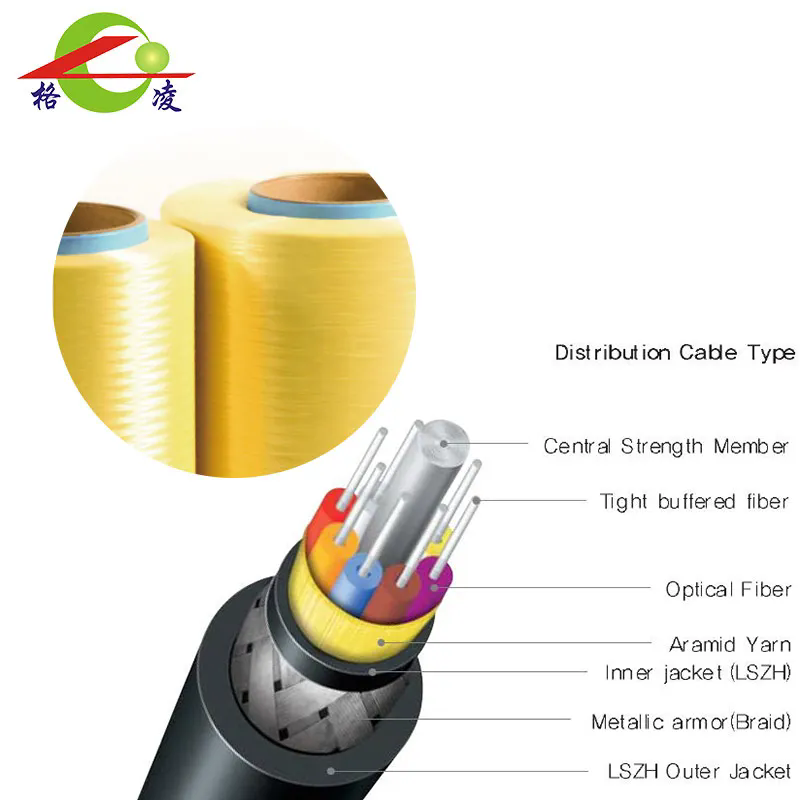

- Ropes and Cables: The fibers are utilized in the production of high-strength ropes and cables for applications requiring robust and reliable performance.

Benefits of Para-Aramid Filament

1. Enhanced Performance

- Strength-to-Weight Ratio: The high strength-to-weight ratio of para-aramid filaments allows for the creation of lightweight yet exceptionally strong products, improving performance and efficiency.

- Durability: The durability and resistance to wear and tear extend the lifespan of products made from para-aramid fibers, reducing the need for frequent replacements.

2. Safety and Protection

- Ballistic Protection: In applications such as body armor, para-aramid fibers provide superior protection against ballistic threats, enhancing safety for military personnel and law enforcement.

- Heat Protection: The material’s resistance to high temperatures and flames offers additional safety in environments exposed to heat or fire hazards.

3. Versatility

- Broad Applications: Para-aramid filaments can be tailored to various applications, from aerospace to sports equipment, thanks to their unique properties and versatility.

- Customization: The fibers can be woven into different fabrics and combined with other materials to meet specific performance requirements.

Future Developments and Innovations

1. Advanced Manufacturing Techniques

- Nanotechnology: Researchers are exploring the use of nanotechnology to enhance the properties of para-aramid fibers, such as improving their impact resistance and flexibility.

- Sustainable Production: Efforts are underway to develop more sustainable manufacturing processes for para-aramid fibers, reducing environmental impact while maintaining performance.

2. New Applications

- Wearable Technology: Innovations in wearable technology may lead to new applications for para-aramid fibers in smart textiles and advanced protective gear.

- Automotive Innovations: Continued advancements in the automotive industry may drive the development of new para-aramid applications in high-performance and safety-critical components.

Conclusion

Para-aramid filament is a remarkable material that brings unparalleled strength, durability, and safety to a wide range of applications. Its unique properties, including high tensile strength, heat and flame resistance, and impact absorption, make it an invaluable component in industries such as aerospace, automotive, sports, and industrial safety.

As technology advances and new applications emerge, para-aramid filaments will continue to play a vital role in enhancing performance and safety. Understanding the benefits and potential of this innovative material can help industries leverage its properties to develop cutting-edge solutions and drive future advancements.