The Importance of the Brick Machine Curing Room in Modern Brick Production

2024-09-06

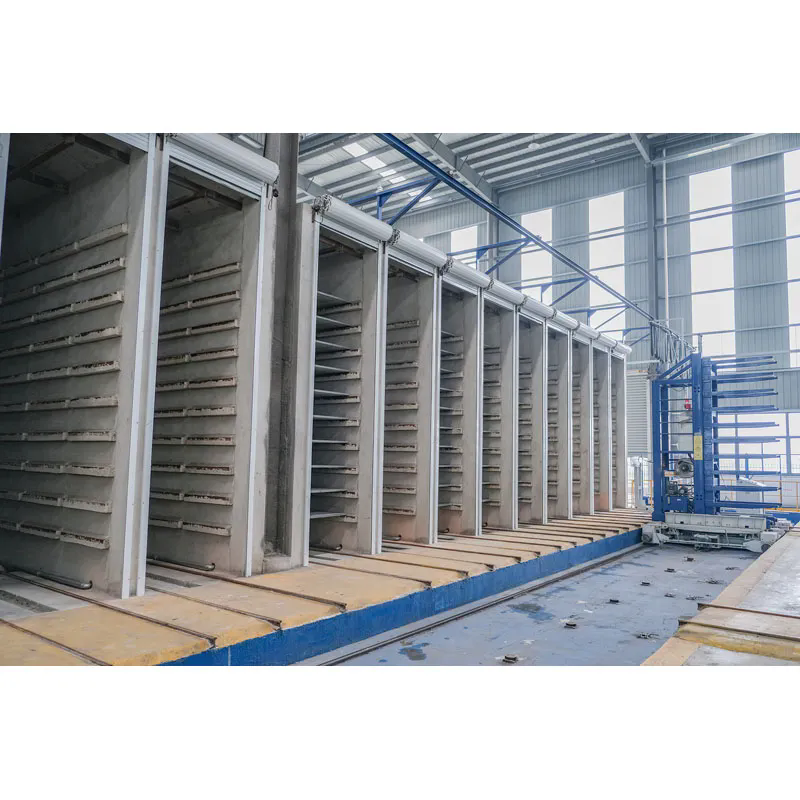

In the brick manufacturing industry, the curing process is as crucial as the initial molding and drying stages. The brick machine curing room plays a pivotal role in ensuring the quality and durability of the final product. This specialized environment helps optimize the curing process, leading to stronger and more reliable bricks. Here’s an in-depth look at why the brick machine curing room is essential and how it impacts brick production.

What is a Brick Machine Curing Room?

A brick machine curing room is a controlled environment where freshly molded bricks are stored to undergo the curing process. Curing is a critical step that involves maintaining optimal conditions for the bricks to gain strength and durability. The curing room provides the necessary temperature, humidity, and ventilation to ensure that the bricks cure properly and achieve their desired properties.

Why is the Brick Machine Curing Room Important?

1. Optimized Curing Conditions:

The brick machine curing room is designed to maintain precise conditions that are essential for effective curing. By controlling factors such as temperature and humidity, the curing room ensures that bricks cure uniformly and reach their full potential in terms of strength and durability. This controlled environment helps prevent issues like cracking or incomplete curing, which can affect the quality of the bricks.

2. Enhanced Brick Strength and Durability:

Proper curing in the brick machine curing room leads to improved strength and durability of the bricks. When bricks are cured under optimal conditions, they develop the necessary hardness and resistance to environmental factors. This results in a higher quality product that performs well in construction applications, providing long-lasting durability and reliability.

3. Increased Production Efficiency:

The efficiency of the brick production process is greatly influenced by the curing stage. A well-designed brick machine curing room streamlines the curing process, allowing for consistent and high-quality output. By ensuring that bricks are properly cured, manufacturers can reduce the likelihood of defects and rework, leading to more efficient production and better overall productivity.

4. Cost Savings:

Proper curing in the brick machine curing room can lead to significant cost savings for brick manufacturers. High-quality bricks that are cured effectively reduce the need for costly repairs or replacements in construction projects. Additionally, optimizing the curing process minimizes waste and enhances resource utilization, contributing to lower production costs.

5. Regulatory Compliance:

In many regions, there are specific regulations and standards governing the quality of construction materials, including bricks. The brick machine curing room helps manufacturers comply with these standards by ensuring that bricks meet the required specifications for strength and durability. Adhering to these regulations is essential for maintaining a good reputation and securing contracts in the construction industry.

Key Features of an Effective Brick Machine Curing Room

- Temperature and Humidity Control: Advanced systems to regulate and maintain optimal curing conditions.

- Ventilation: Proper airflow to ensure even curing and prevent moisture accumulation.

- Monitoring Equipment: Tools to track and record environmental conditions and brick quality.

- Automated Systems: Automation for efficient management of the curing process and data collection.

Conclusion

The brick machine curing room is a vital component of the brick production process, ensuring that bricks are cured under optimal conditions to achieve maximum strength and durability. By providing a controlled environment, manufacturers can enhance the quality of their bricks, improve production efficiency, and reduce costs. As the demand for high-quality construction materials continues to grow, the role of the brick machine curing room becomes increasingly important in delivering reliable and durable products. Understanding and investing in effective curing practices will ultimately contribute to the success and reputation of brick manufacturing operations.