Rubber Compound: The Science Behind Performance and Durability

2025-03-12

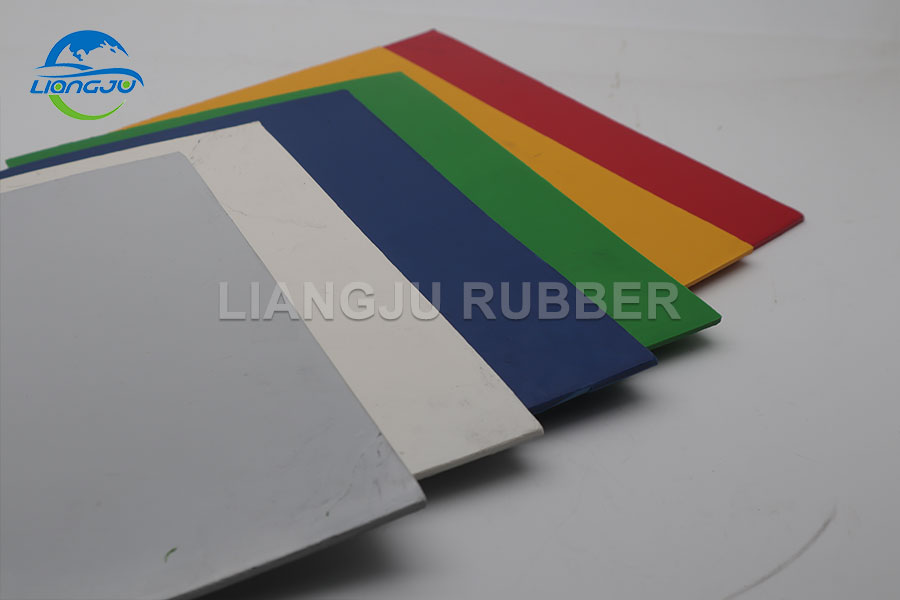

Rubber is everywhere, from car tires to industrial seals and even everyday household items. But have you ever wondered what makes rubber materials so versatile? The answer lies in rubber compounds, carefully engineered mixtures that enhance the properties of raw rubber to meet specific performance demands.

Whether in automotive, aerospace, medical, or consumer goods, rubber compounds play a crucial role in modern manufacturing. Let’s dive into what makes rubber compounds so essential and how they are shaping the future of material innovation.

What Is a Rubber Compound?

A rubber compound is a customized blend of raw rubber, fillers, curing agents, and performance-enhancing additives. These components work together to modify characteristics such as flexibility, strength, durability, and resistance to heat, chemicals, and wear.

By adjusting the composition, manufacturers can create rubber materials tailored for high-performance applications, from extreme temperature environments to high-stress industrial operations.

Key Components of a Rubber Compound

1. Base Polymer

The core ingredient of any rubber compound, the base polymer determines fundamental properties like elasticity, strength, and resistance. Common types include natural rubber (NR), synthetic rubber (SBR, EPDM, NBR), and high-performance elastomers like silicone and fluorocarbon rubber.

2. Fillers and Reinforcements

Materials like carbon black and silica improve the mechanical strength, wear resistance, and longevity of the rubber. Different fillers are used depending on the application, whether it’s enhancing grip in tires or increasing insulation in industrial seals.

3. Curing Agents

Also known as vulcanizing agents, these ingredients create cross-links between polymer chains, strengthening the rubber and improving heat resistance. Sulfur and peroxide are commonly used to control elasticity and toughness.

4. Plasticizers and Softeners

These additives modify flexibility and processing characteristics, ensuring the rubber remains soft and workable during production. They also enhance low-temperature performance in cold environments.

5. Antioxidants and UV Stabilizers

To prevent rubber from degrading over time, stabilizers protect against oxidation, heat, and UV exposure, ensuring a longer service life in outdoor and high-heat applications.

Why Rubber Compounds Matter

- Enhanced Performance: Custom formulations allow rubber to be heat-resistant, oil-resistant, chemical-resistant, or abrasion-resistant, depending on the application.

- Durability in Harsh Environments: Whether exposed to extreme temperatures, heavy loads, or corrosive chemicals, rubber compounds provide long-term reliability.

- Versatility Across Industries: From automotive tires and industrial gaskets to medical-grade seals and electrical insulation, rubber compounds are everywhere.

Future Trends in Rubber Compounding

As industries evolve, so do the demands for more advanced rubber materials. Some key trends shaping the future include:

- Sustainable Rubber: The push for eco-friendly materials is leading to innovations in bio-based rubber and recycled compounds, reducing environmental impact without compromising performance.

- High-Performance Elastomers: Cutting-edge rubber compounds are being developed for aerospace, medical, and electronic applications, offering superior resistance to extreme conditions.

- Smart Materials: The integration of self-healing and conductive rubber compounds is unlocking new possibilities in flexible electronics and wearable technology.

Conclusion

Rubber compounds are more than just a blend of materials; they are the foundation of high-performance, durable, and versatile products across countless industries. As technology advances, the science behind rubber compounding continues to evolve, bringing us stronger, more efficient, and more sustainable materials for the future.

Whether you’re in manufacturing, engineering, or simply curious about material science, rubber compounds are a fascinating world worth exploring. What application interests you the most? Let’s discuss in the comments!