Maximizing Machining Efficiency with ER Tool Holder Rods

2024-08-26

In the world of precision machining, the tools and equipment you choose can make a significant difference in the quality of your work and the efficiency of your operations. Among the essential components in any machine shop are tool holders, and one of the most reliable and versatile options available is the ER tool holder rod. In this blog, we’ll explore the importance of ER tool holder rods, their key features, and how they contribute to optimal machining performance.

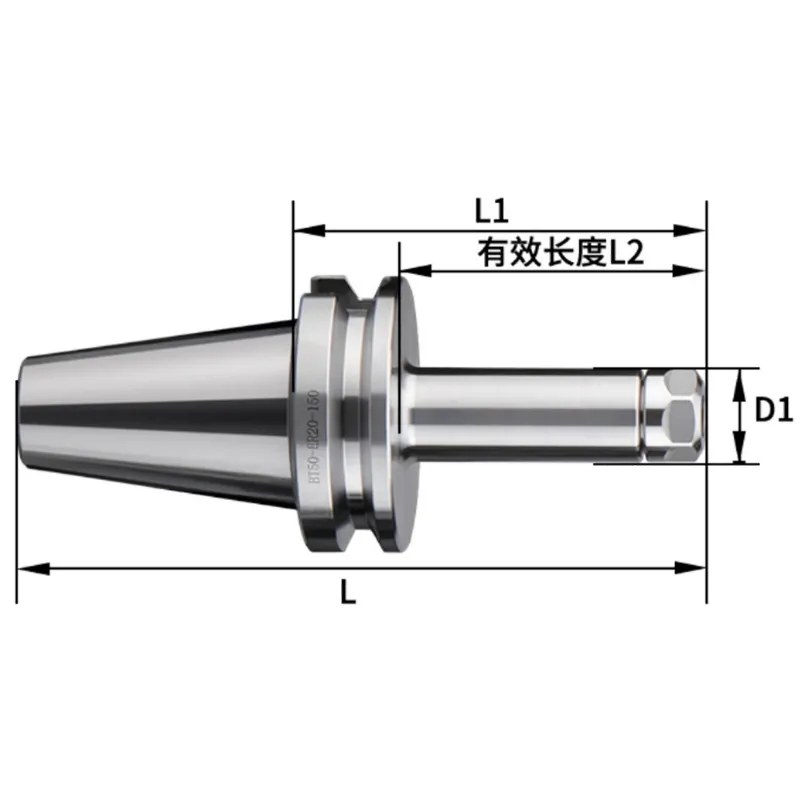

What is an ER Tool Holder Rod?

An ER tool holder rod is a type of tool holder used to securely clamp cutting tools in a CNC (Computer Numerical Control) machine. The "ER" stands for "Elastic Rubber," which refers to the collet system used in these tool holders. ER collets are designed to grip the tool with high precision and clamping force, ensuring stability during high-speed machining operations.

The ER tool holder rod is widely used in milling, drilling, and turning applications, making it a staple in various manufacturing environments. It is compatible with a range of tool sizes, providing flexibility for different machining tasks.

Key Features of ER Tool Holder Rods

1. High Precision and Stability: ER tool holder rods are known for their exceptional precision and stability. The ER collet system provides a tight grip on the cutting tool, minimizing tool runout and ensuring consistent performance. This precision is critical in achieving high-quality finishes and accurate machining.

2. Versatility: One of the standout features of ER tool holder rods is their versatility. They can accommodate a wide range of tool shank sizes, thanks to the ER collets, which are available in various sizes. This versatility makes ER tool holders suitable for a variety of machining tasks, from light milling to heavy-duty drilling.

3. Strong Clamping Force: The design of the ER collet system allows for a strong clamping force, which is essential for holding the tool securely during high-speed operations. This clamping force reduces the risk of tool slippage, which can lead to inaccuracies and tool breakage.

4. Easy Tool Changes: ER tool holder rods are designed for quick and easy tool changes. The collet nut can be easily loosened to release the tool, making it simple to switch between different cutting tools without significant downtime. This feature enhances productivity and efficiency in the workshop.

5. Compatibility with Various Machines: ER tool holder rods are compatible with a wide range of CNC machines, making them a versatile choice for machine shops that work with different types of equipment. They are commonly used in vertical and horizontal machining centers, lathes, and other CNC machinery.

6. Durable Construction: ER tool holder rods are typically made from high-quality materials such as alloy steel or hardened steel, which ensures durability and long service life. The robust construction allows them to withstand the demands of high-speed machining and heavy workloads.

Benefits of Using ER Tool Holder Rods

1. Enhanced Machining Accuracy: The high precision and stability offered by ER tool holder rods contribute to enhanced machining accuracy. This accuracy is essential in producing parts with tight tolerances and intricate details.

2. Reduced Tool Wear: The secure grip provided by the ER collet system reduces tool vibration and runout, which in turn minimizes tool wear. This extends the lifespan of cutting tools and reduces the frequency of tool replacements, leading to cost savings.

3. Increased Productivity: With easy tool changes and strong clamping force, ER tool holder rods help increase productivity in the workshop. Operators can quickly switch between tools and maintain consistent performance, leading to faster turnaround times on machining projects.

4. Versatile Applications: The ability to accommodate various tool sizes and work with different CNC machines makes ER tool holder rods a versatile option for a wide range of applications. Whether you’re milling, drilling, or turning, these tool holders can meet the demands of different tasks.

5. Cost-Effective Solution: ER tool holder rods offer a cost-effective solution for machine shops looking to invest in reliable and versatile tooling. Their durability, combined with the extended tool life they provide, results in lower overall operational costs.

Applications of ER Tool Holder Rods

- CNC Milling: ER tool holder rods are commonly used in CNC milling applications where precision and stability are crucial. They can hold various types of milling cutters, ensuring accurate and efficient material removal.

- CNC Drilling: In drilling operations, ER tool holders provide the necessary clamping force to prevent tool slippage, even during deep drilling tasks. This results in clean, precise holes and reduces the risk of tool breakage.

- Turning: In turning applications, ER tool holder rods can be used to hold boring bars, grooving tools, and other cutting tools. Their stability and precision help achieve smooth finishes and accurate dimensions on turned parts.

- Engraving and Cutting: For engraving and cutting tasks that require fine detail and precision, ER tool holder rods offer the necessary stability to produce high-quality results.

Conclusion

ER tool holder rods are a vital component in any machine shop, offering the precision, stability, and versatility needed for a wide range of machining applications. Their robust construction, combined with the reliable ER collet system, ensures that your tools are held securely, minimizing the risk of inaccuracies and tool wear. Whether you’re working on complex CNC milling projects or simple drilling tasks, investing in high-quality ER tool holder rods can significantly enhance your machining performance and productivity.