Key points regarding Centerless Grinding Wheel

2023-11-14

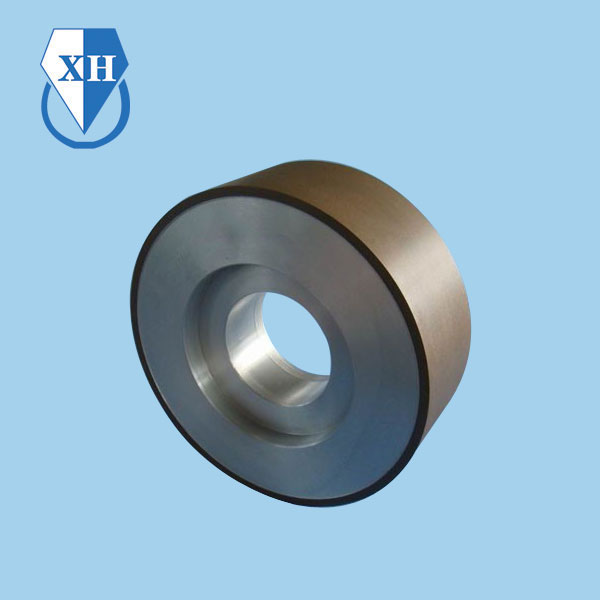

A centerless grinding wheel is a specialized type of grinding wheel used in centerless grinding, a machining process that involves the removal of material from a workpiece without the use of centers or chucks. Here are key points regarding centerless grinding wheels:

1. Purpose of Centerless Grinding:

- Through-Feed Grinding: Centerless grinding is commonly used for through-feed grinding, where the workpiece is passed between two grinding wheels and ground along its entire length.

- Infeed Grinding: In some cases, centerless grinding wheels are also used for infeed grinding, where material is removed from the workpiece incrementally.

2. Composition and Design:

- Bond Type: Centerless grinding wheels can have different types of bonds, such as resin, vitrified, or metal bonds, depending on the specific requirements of the application.

- Abrasive Material: The abrasive material on the wheel can vary and may include aluminum oxide, silicon carbide, ceramic, or diamond, depending on the hardness of the workpiece material.

- Wheel Shape: The wheels used in centerless grinding typically have a specific shape conducive to the centerless grinding process.

3. Structure and Density:

- Wheel Structure: The structure of the grinding wheel refers to the arrangement of abrasive grains in the wheel. Open structures allow for more chip clearance, while dense structures provide finer surface finishes.

- Density: The density of the abrasive grains on the wheel affects the material removal rate and the surface finish. Lower-density wheels may be used for faster material removal, while higher-density wheels can achieve finer finishes.

4. Wheel Sizes:

- Diameter and Thickness: Centerless grinding wheels come in various diameters and thicknesses to suit different machines and applications.

- Regulating Wheel: In centerless grinding, there is not only the grinding wheel but also a regulating wheel. The relative sizes and speeds of these wheels are critical for the grinding process.

5. Cooling and Lubrication:

- Coolant Usage: Centerless grinding wheels may be used with coolant to dissipate heat generated during the grinding process and to improve the surface finish.

- Lubrication: Lubrication may be used to reduce friction between the wheels and the workpiece.

6. Applications:

- Cylindrical Components: Centerless grinding is often used for cylindrical components, such as shafts, pins, and rollers, where precise diameter control is crucial.

- High Production Rates: Centerless grinding is known for its high production rates, making it suitable for applications where large quantities of parts need to be processed efficiently.

7. Safety Precautions:

- Proper Use of PPE: As with any grinding operation, operators should use appropriate personal protective equipment (PPE), including safety glasses, face shields, and gloves.

- Machine Guards: Ensuring that the grinding machine has proper guards in place is essential for operator safety.

It's important to follow the manufacturer's guidelines and recommendations for the specific type of centerless grinding wheel being used, as specifications may vary based on the wheel's design and intended applications.