How Can Precision Floats Improve Accuracy and Efficiency in Industrial Applications?

2025-02-26

In various industrial fields, achieving the highest level of precision is key to ensuring safety, efficiency, and reliability. Among the tools and components that facilitate such precision, precision floats are becoming increasingly significant. These specialized instruments are designed to provide accurate measurements of liquid levels, and their applications span across industries like automotive, manufacturing, water treatment, and even food processing. But how exactly can precision floats improve accuracy and efficiency in these diverse industrial applications?

What is a Precision Float and How Does it Work?

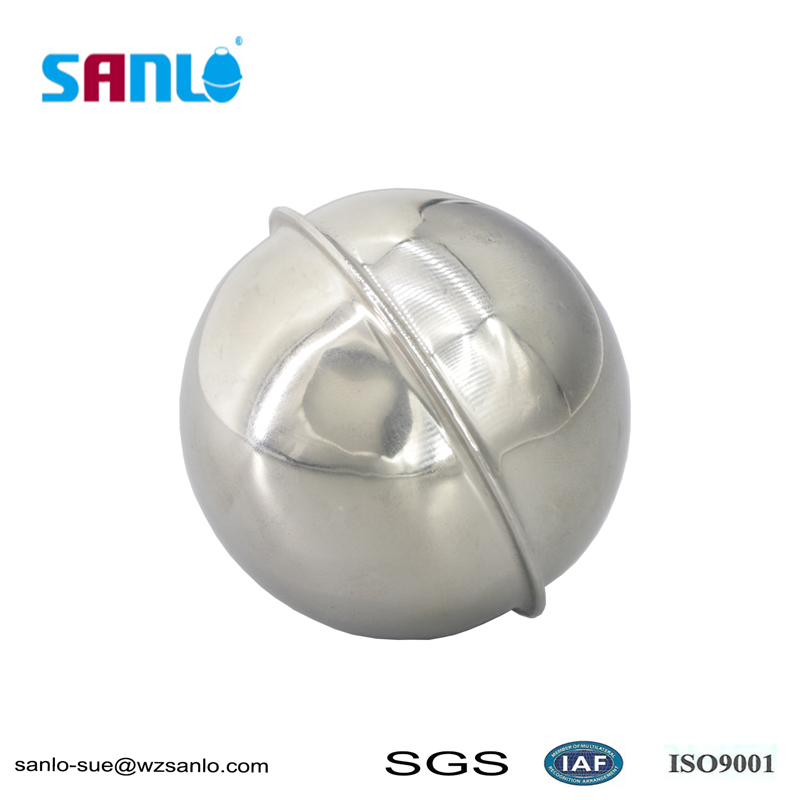

A precision float is an essential component used in fluid level sensing systems, commonly employed in tanks, vessels, or pipelines where it’s critical to monitor the level of a liquid. Typically, these floats consist of a buoyant material that floats on top of the liquid, with a built-in sensor mechanism that sends readings regarding the fluid's height or level. These floats are designed with exceptional accuracy, ensuring that the measurements are highly reliable and precise, which is crucial for many industrial processes.

The float's sensor is often connected to an electronic system that can trigger alarms or automatic adjustments if the liquid level goes beyond the desired threshold. This ability to track and adjust fluid levels plays a vital role in maintaining operational efficiency and safety in many industrial settings.

How Do Precision Floats Improve Accuracy?

1. Highly Sensitive Sensing Capabilities

Precision floats are designed to be extremely sensitive to small changes in liquid levels. The float’s sensor system can detect even minute shifts in the height of the liquid, providing accurate readings in real-time. This sensitivity is especially valuable in systems where small fluctuations can lead to significant problems, such as in chemical processing, pharmaceuticals, or food production, where exact quantities of liquids must be handled with precision.

2. Enhanced Measurement Reliability

One of the key advantages of using precision floats is their ability to deliver consistent and reliable measurements over time. Unlike manual methods, which may be subject to human error, precision floats are automated and designed to ensure accuracy and repeatability. This reliability reduces the chances of measurement discrepancies, which could lead to overflows, equipment damage, or wastage of expensive raw materials.

3. High-Resolution Monitoring

In many industrial applications, operators need to monitor liquid levels with high resolution for effective decision-making. Precision floats are capable of providing this level of detail, allowing for more accurate adjustments in the system. Whether it’s regulating a chemical mix in a manufacturing plant or ensuring the precise level of coolant in machinery, high-resolution measurements contribute to more efficient processes.

4. Adaptability to Different Liquids and Environments

Precision floats are designed to work in a variety of environments and with different types of liquids, from clean water to corrosive chemicals. Whether the system deals with highly viscous liquids or volatile substances, precision floats can be engineered to withstand these conditions without compromising their accuracy. This adaptability makes them indispensable in industries where the properties of the fluids vary or where harsh environmental conditions are a factor.

How Do Precision Floats Enhance Efficiency in Industrial Processes?

1. Automation of Fluid Level Control

One of the most significant ways precision floats improve efficiency is through the automation of fluid level control. In industries where tanks or reservoirs hold liquids, maintaining a consistent level is crucial for the operation of equipment and the quality of the final product. Precision floats work with automated control systems to monitor fluid levels continuously and adjust them as needed, reducing the need for manual monitoring and intervention. This automated control not only enhances productivity but also reduces the chances of human error.

2. Prevention of Overflows and Spillage

Overflowing liquids can lead to safety hazards, wastage of resources, and environmental contamination. Precision floats play an important role in preventing overflows by triggering automatic shutoffs or alarms when fluid levels rise too high. This early detection and prevention help avoid costly accidents, minimize waste, and improve overall operational safety in industrial environments.

3. Optimizing Resource Usage

In industries such as food and beverage manufacturing or chemicals, the precise control of liquid quantities can have a direct impact on resource optimization. With the help of precision floats, operators can maintain ideal liquid levels, ensuring that resources are used efficiently, without excess or shortage. By eliminating overfilling or underfilling, businesses can save on raw materials, energy consumption, and labor costs.

4. Improving System Monitoring and Maintenance

Precision floats also contribute to better overall system monitoring and maintenance. Continuous, accurate readings of liquid levels enable operators to identify potential problems in the system before they escalate into major issues. Whether it’s detecting leaks, malfunctioning equipment, or the need for maintenance, precision floats provide early warnings that help reduce downtime and costly repairs, ultimately improving the lifespan and reliability of equipment.

What Are the Different Applications of Precision Floats in Various Industries?

1. Chemical Processing

In the chemical industry, precision floats are widely used to monitor the levels of various chemicals in storage tanks and reactors. These measurements are crucial for maintaining the proper chemical balance and ensuring safety. Accurate fluid level monitoring also helps maintain the correct mixing ratios, preventing costly mistakes and reducing waste.

2. Automotive Industry

The automotive industry uses precision floats to monitor fuel levels, coolant systems, and other essential fluid levels in vehicles and manufacturing equipment. These floats provide accurate readings that are essential for the proper functioning of engines, ensuring that the right amounts of fuel and coolant are available at all times.

3. Water Treatment Plants

In water treatment plants, precision floats are used to measure the water levels in various treatment stages. This ensures that water flows through the system as intended and maintains the proper chemical balance for purification processes. Accurate fluid level monitoring also helps optimize the treatment process and reduce the consumption of chemicals.

4. Food and Beverage Production

In the food and beverage industry, precision floats are crucial for maintaining the right liquid levels in mixing tanks, fermentation vessels, and storage tanks. The need for cleanliness, accuracy, and consistency is paramount in this industry, and precision floats help ensure that all products are prepared according to stringent quality standards.

How Can Businesses Choose the Right Precision Float?

Selecting the right precision float for a specific application involves considering several factors, including:

1. Material Compatibility – Choose a float material that can handle the type of fluid it will be exposed to. Corrosive chemicals, high temperatures, and high-pressure environments will require durable, specialized materials.

2. Accuracy Requirements – Consider the level of accuracy required for the specific process. For highly sensitive operations, a precision float with high resolution and repeatability will be essential.

3. Size and Design – The float’s size and design must be suitable for the tank or system in which it will be installed. Custom designs may be necessary for unique or complex systems.

4. Environmental Conditions – Ensure the float can withstand the environmental conditions of the installation site, including exposure to extreme temperatures, humidity, or hazardous materials.

Conclusion

Precision floats are essential tools for achieving accurate and efficient fluid level monitoring in industrial applications. Their ability to provide reliable measurements, prevent overflows, automate control systems, and optimize resource usage makes them indispensable in industries such as chemical processing, automotive, water treatment, and food production. By incorporating precision floats into your system, businesses can improve operational efficiency, enhance safety, and reduce costs, ensuring a more reliable and productive operation overall.