How Can Multilayer FPC Revolutionize the Future of Electronics and Flexible Devices?

2025-02-26

The world of electronics is constantly evolving, with new innovations leading to the creation of smaller, faster, and more efficient devices. One such advancement that has gained immense popularity in recent years is Multilayer FPC (Flexible Printed Circuit) technology. But how exactly can multilayer FPCs revolutionize the future of electronics and flexible devices? Let’s explore how this versatile and efficient technology is reshaping industries from consumer electronics to medical devices.

What is Multilayer FPC and How Does It Work?

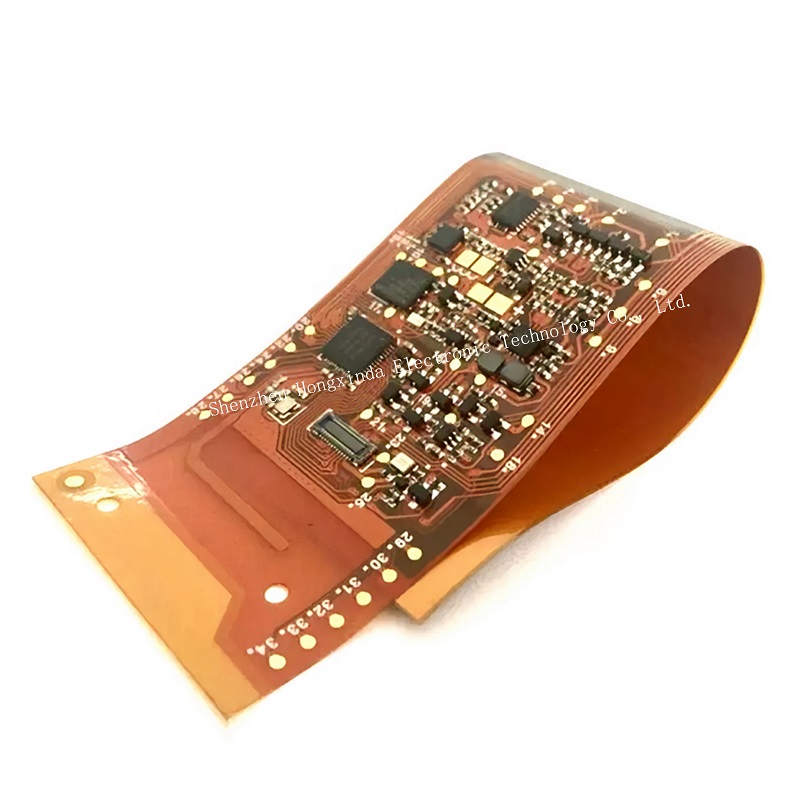

Multilayer FPC is an advanced type of flexible printed circuit board that features multiple conductive layers, stacked and interconnected to create complex circuits. Unlike traditional rigid circuit boards, FPCs are made from flexible materials such as polyimide, which allows them to bend and conform to different shapes and sizes. These flexible, multilayer circuits are engineered with precision to ensure the layers are electrically connected while maintaining flexibility and durability.

The construction of multilayer FPC typically involves several layers of conductive material (such as copper), which are separated by insulating layers. These layers are interconnected through vias (holes) that allow signals and power to flow between different layers, creating a fully functional circuit that can bend, fold, and twist without compromising performance.

Why Are Multilayer FPCs Gaining Popularity?

1. Space Efficiency

One of the primary advantages of multilayer FPC is its ability to save space. Traditional rigid circuit boards can be bulky and require additional connectors and components for wiring. Multilayer FPCs, on the other hand, integrate multiple circuits into a single, compact unit, allowing electronics to become smaller, more lightweight, and more efficient. This compact nature makes multilayer FPC ideal for modern consumer electronics, such as smartphones, wearable devices, and other portable gadgets where size matters.

2. Design Flexibility

Multilayer FPCs offer unmatched design flexibility due to their ability to bend, fold, and stretch. This adaptability makes them a key component in flexible devices, such as bendable screens, wearable health trackers, and electronic textiles. The flexibility of FPCs allows manufacturers to create designs that were previously impossible with rigid PCBs, such as circuits that can conform to the shape of a product or fit into tight spaces.

3. Durability and Reliability

Despite being flexible, multilayer FPCs are highly durable and reliable. They can withstand physical stresses such as bending, twisting, and vibration, making them ideal for applications in environments that require robustness. This durability ensures a longer lifespan for the electronic devices that incorporate them, reducing the likelihood of failure or damage, even in rugged environments like automotive systems or military equipment.

4. High Performance

Multilayer FPCs offer excellent electrical performance, making them suitable for high-speed applications. With the ability to handle more complex circuit designs, they can transmit signals with minimal signal loss or interference. As electronics become faster and more powerful, the need for high-performance circuits is greater than ever, and multilayer FPCs meet these demands with ease.

How Are Multilayer FPCs Used in Various Industries?

1. Consumer Electronics

The consumer electronics industry is one of the largest beneficiaries of multilayer FPC technology. Devices like smartphones, tablets, and laptops have adopted flexible circuits to improve performance while reducing their size. FPCs allow these devices to incorporate complex circuits that are thin, lightweight, and capable of withstanding everyday wear and tear. Additionally, the flexibility of multilayer FPCs has made possible innovations like foldable smartphones and flexible displays, providing a glimpse into the future of consumer technology.

2. Wearable Technology

The rise of wearable technology, including smartwatches, fitness trackers, and medical devices, has pushed the demand for flexible and compact circuit designs. Multilayer FPCs enable these wearable devices to pack more features into a smaller form factor without sacrificing comfort. The flexibility of FPCs allows them to conform to the shape of the body, providing a comfortable fit while maintaining high-performance functionality.

3. Medical Devices

In the medical field, multilayer FPCs are being used in applications ranging from diagnostic equipment to implantable devices. Their compact size and flexibility make them ideal for devices that need to fit into tight spaces or conform to the contours of the body. For example, flexible circuits are used in portable ECG monitors, hearing aids, and wearable health monitoring devices. The durability of multilayer FPCs ensures that these devices remain operational even under harsh conditions, providing reliable performance for patients and healthcare professionals.

4. Automotive Industry

The automotive industry has also embraced multilayer FPC technology for various applications. Flexible circuits are used in car infotainment systems, sensors, navigation systems, and more. The automotive industry requires high-performance circuits that can operate in a wide range of temperatures and endure vibrations, which multilayer FPCs can easily handle. Additionally, the compact design of multilayer FPCs allows for easier integration into the complex electronic systems found in modern vehicles.

5. Industrial and Aerospace Applications

In industrial and aerospace applications, multilayer FPCs are used in control systems, robotics, avionics, and more. These industries demand circuits that can perform reliably under extreme conditions, such as high altitudes, temperature fluctuations, and exposure to radiation. Multilayer FPCs meet these requirements while offering a lightweight and flexible solution to accommodate space constraints and performance needs.

What Are the Key Advantages of Multilayer FPC in Modern Electronics?

1. Reduction in Manufacturing Costs

Although multilayer FPCs can be more expensive to produce compared to traditional circuit boards, their ability to reduce the size of devices and eliminate the need for additional wiring and connectors can lead to lower overall manufacturing costs. By integrating multiple layers into a single, compact unit, manufacturers can streamline production processes, reduce material waste, and minimize the number of components needed, ultimately lowering the total cost of production.

2. Customization and Integration

Multilayer FPCs can be customized to meet specific requirements, such as adding more layers, adjusting the thickness of the conductive material, or incorporating special materials for unique applications. This level of customization makes them highly versatile for a wide range of industries. Furthermore, multilayer FPCs can integrate additional components, such as resistors, capacitors, and sensors, directly onto the circuit board, further reducing the complexity of the device and improving overall performance.

3. Improved Heat Dissipation

As electronic devices continue to become more powerful, heat dissipation becomes a critical factor in ensuring reliability and performance. Multilayer FPCs are designed to effectively dissipate heat, preventing overheating and maintaining optimal functionality. The layers in the circuit board can be designed to enhance thermal conductivity, ensuring that the device remains cool even under heavy usage.

Conclusion

Multilayer FPCs are at the forefront of the next generation of flexible and compact electronic devices. With their ability to provide space-efficient, high-performance, and durable solutions, they are revolutionizing industries ranging from consumer electronics to medical devices. By offering design flexibility and customization, multilayer FPCs are making it possible to create more complex, efficient, and reliable products, all while pushing the boundaries of what is possible in electronics. As the demand for smaller, faster, and more powerful devices continues to rise, multilayer FPCs will undoubtedly play a key role in shaping the future of technology.