Features of PEEK Capillary Tubing

2024-06-20

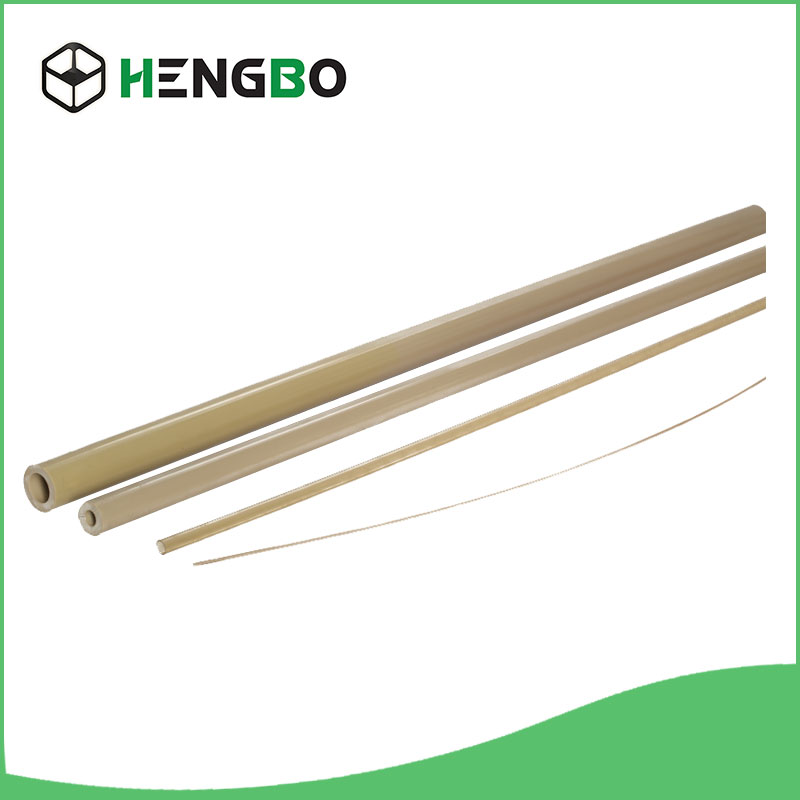

PEEK (Polyetheretherketone) capillary tubing is a specialized type of tubing used in various scientific, medical, and industrial applications where high-performance materials are required. PEEK is known for its exceptional mechanical properties, chemical resistance, and thermal stability, making it suitable for demanding environments. Here’s an overview of PEEK capillary tubing, its features, applications, and benefits:

Features of PEEK Capillary Tubing:

1. Material Properties:

- High Temperature Resistance: Can withstand continuous operating temperatures up to 250°C (482°F) and short-term exposure to even higher temperatures.

- Chemical Resistance: Resistant to a wide range of chemicals, including organic solvents, acids, and bases, making it suitable for aggressive environments.

- Mechanical Strength: Exhibits high tensile strength, stiffness, and fatigue resistance, providing durability and reliability in use.

- Low Friction: Has a low coefficient of friction, which facilitates smooth fluid flow and reduces the risk of blockages.

2. Precision Manufacturing:

- Uniform Dimensions: Capillary tubing is manufactured with precise inner and outer diameters to ensure consistent flow rates and compatibility with fittings.

- Smooth Internal Surface: Minimizes adsorption and enhances sample purity in analytical applications.

3. Biocompatibility:

- PEEK is biocompatible and widely used in medical and pharmaceutical applications where contact with bodily fluids or tissues is required.

4. Flexibility and Durability:

- Despite its rigidity, PEEK capillary tubing can be flexible enough to be coiled or bent without kinking, maintaining integrity over time.

Applications of PEEK Capillary Tubing:

1. Chromatography:

- Used in liquid chromatography (HPLC, UHPLC) and gas chromatography (GC) systems for separating and analyzing chemical compounds.

- Provides excellent chemical resistance and minimal adsorption, which is critical for accurate analytical results.

2. Medical and Pharmaceutical:

- Drug Delivery Systems: PEEK tubing is employed in catheters and implantable medical devices due to its biocompatibility and chemical inertness.

- Bioprocessing: Used in biopharmaceutical manufacturing for fluid transfer and sample handling in sterile environments.

3. Industrial Applications:

- Fluid Handling: PEEK capillary tubing is utilized in industrial fluid handling systems, such as inks, dyes, and aggressive chemicals.

- Automotive and Aerospace: Applications where high-temperature stability and chemical resistance are required, such as fuel lines and hydraulic systems.

4. Electronics and Semiconductors:

- Used in microfluidic devices and analytical instruments for precise fluid handling and control.

Benefits of PEEK Capillary Tubing:

- High Performance: Maintains mechanical and chemical properties over a wide range of temperatures and environments.

- Versatility: Suitable for diverse applications across industries due to its combination of strength, flexibility, and chemical resistance.

- Longevity: Resistant to degradation, ensuring extended service life and reliability in critical applications.

- Ease of Handling: Lightweight and easy to install, reducing labor and assembly time in manufacturing processes.

Considerations:

- Cost: PEEK is more expensive than traditional polymers like PVC or polyethylene, but its performance benefits justify the investment in demanding applications.

- Compatibility: Ensure compatibility with other system components and fluids to prevent material degradation or compatibility issues.

Conclusion:

PEEK capillary tubing is a high-performance material widely used in analytical, medical, and industrial applications where durability, chemical resistance, and precise fluid handling are critical. Its superior properties make it a preferred choice for applications requiring reliability, longevity, and performance under challenging conditions. Understanding the features, applications, benefits, and considerations of PEEK capillary tubing helps industries and researchers leverage its capabilities effectively in their respective fields.