Detailed Overview of Auto Extrusion Aluminum Tubes

2024-07-31

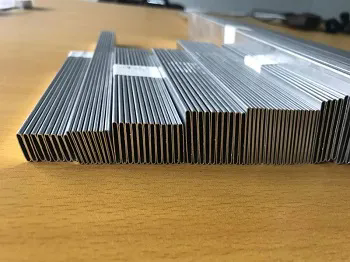

Auto extrusion aluminum tubes are produced through an extrusion process, which involves forcing aluminum through a die to create long tubes of a specific cross-sectional profile. This manufacturing technique is used to produce aluminum tubes with consistent dimensions and high strength, making them ideal for various automotive applications. Here’s a detailed overview:

Key Features

1. Material:

- Aluminum Alloy: Typically made from aluminum alloys such as 6061, 6063, or 7075, which offer a good balance of strength, weight, and corrosion resistance.

2. Extrusion Process:

- Hot Extrusion: The aluminum billet is heated to a high temperature and then pushed through a die to create the desired tube shape.

- Cold Extrusion: Involves shaping the aluminum at room temperature or slightly elevated temperatures, often used for smaller or more precise tubes.

3. Tube Dimensions:

- Custom Sizes: Can be produced in various diameters, wall thicknesses, and lengths to meet specific requirements.

- Tolerances: High precision in dimensions and tolerances ensures a consistent and reliable product.

4. Surface Finish:

- Anodizing: Commonly anodized to enhance corrosion resistance and aesthetic appeal.

- Powder Coating: May be powder-coated for added protection and color options.

- Mill Finish: Basic, untreated surface that maintains the natural appearance of the aluminum.

5. Strength and Durability:

- High Strength-to-Weight Ratio: Aluminum provides a good strength-to-weight ratio, which is beneficial in automotive applications where weight reduction is important.

- Corrosion Resistance: Aluminum is naturally resistant to corrosion, making it suitable for automotive parts exposed to various environmental conditions.

Benefits

1. Lightweight:

- Reduced Weight: Aluminum is much lighter than steel, which helps in reducing the overall weight of the vehicle and improving fuel efficiency.

2. High Strength:

- Structural Integrity: Despite its lightweight nature, aluminum can be extruded to achieve high strength and durability, making it suitable for structural components.

3. Corrosion Resistance:

- Longevity: The natural corrosion resistance of aluminum extends the lifespan of automotive components, even in harsh conditions.

4. Design Flexibility:

- Custom Shapes: The extrusion process allows for complex shapes and profiles, providing design flexibility for various applications.

5. Recyclability:

- Environmental Benefits: Aluminum is highly recyclable, making it an environmentally friendly choice in automotive manufacturing.

Applications

1. Automotive Frames and Chassis:

- Structural Components: Used in the frame and chassis of vehicles to reduce weight while maintaining strength and safety.

2. Heat Exchangers:

- Radiators and Condensers: Commonly used in the construction of radiators and heat exchangers due to its excellent thermal conductivity and lightweight properties.

3. Engine Components:

- Pipes and Tubes: Utilized for various engine components, including intake and exhaust pipes, due to its strength and resistance to heat.

4. Interior Components:

- Trim and Panels: Employed in interior trim and panels for its aesthetic appeal and durability.

5. Suspension Parts:

- Control Arms and Links: Used in suspension systems to enhance performance and reduce weight.

Considerations

1. Cost:

- Material Cost: Aluminum is generally more expensive than some other materials, such as steel. The cost of extrusion and finishing processes should also be considered.

2. Machining and Fabrication:

- Processing Needs: Extruded aluminum tubes may require additional machining or fabrication to meet specific design requirements, adding to the overall cost.

3. Strength Requirements:

- Alloy Selection: Choosing the appropriate aluminum alloy and tube thickness is crucial to ensure that the component meets the required strength and performance standards.

4. Environmental Impact:

- Sustainability: While aluminum is recyclable, the energy-intensive process of extraction and production should be factored into the environmental impact assessment.

Auto extrusion aluminum tubes offer a combination of strength, lightweight properties, and design flexibility, making them suitable for a wide range of automotive applications. The extrusion process ensures consistent quality and precise dimensions, which are essential for performance and safety in automotive components.