Detailed description of Custom Stainless Steel Deep Drawing

2024-06-29

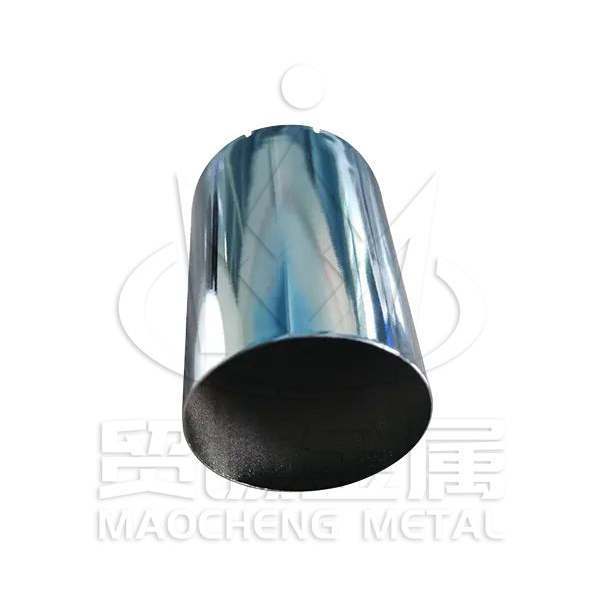

Custom stainless steel deep drawing is a specialized manufacturing process used to create complex, hollow metal components from stainless steel sheets. Here’s a detailed description of what typically characterizes custom stainless steel deep drawing:

1. Material Selection:

- Stainless Steel: Chosen for its corrosion resistance, durability, and aesthetic appeal. Common grades used include 304, 316, and 430 stainless steel, depending on the specific application requirements such as environmental conditions or mechanical properties.

2. Process Overview:

- Blank Preparation: Starts with a flat stainless steel sheet, which is cut into a blank or disc of the required size and shape.

- Tooling Design: Specialized dies and punches are designed according to the final component specifications. These tools are crucial for forming the metal into the desired shape through controlled deformation.

3. Deep Drawing Steps:

- Blank Holder: The stainless steel blank is placed over the die cavity, held in place by a blank holder, and clamped securely.

- Drawing: The punch descends and applies force to the blank, gradually forming it into the shape of the die cavity. This process involves stretching and thinning the metal, often in multiple stages or passes to achieve the final shape.

- Redrawing (if necessary): In some cases, a redrawing process may be employed to further refine the shape or improve dimensional accuracy.

4. Advantages:

- Complex Shapes: Deep drawing allows for the production of intricate and complex geometries that may be difficult or costly to achieve through other manufacturing methods.

- Material Efficiency: Minimizes material waste since the process utilizes the entire sheet, converting it into a finished part with minimal scrap.

- Cost-Effective: Economical for medium to high volume production runs due to efficient material usage and high automation potential.

5. Design Considerations:

- Wall Thickness: Determined based on the component's structural requirements and the capabilities of the deep drawing process.

- Tolerance Requirements: Precision tooling and process control are critical to achieving tight dimensional tolerances specified in the design.

- Surface Finish: The final surface finish can range from matte to highly polished, depending on post-processing treatments or the condition of the tooling.

6. Applications:

- Automotive: Components such as fuel system parts, exhaust system components, and sensor housings.

- Electronics: Enclosures for electronic devices, connectors, and housings for sensitive equipment.

- Household Appliances: Parts for kitchen appliances, HVAC components, and decorative trim.

- Medical: Surgical instruments, equipment housings, and implants (in certain grades of stainless steel).

7. Quality Assurance:

- Inspection: Components undergo rigorous inspection processes to ensure dimensional accuracy, surface quality, and compliance with specifications.

- Testing: Non-destructive testing methods may be employed to verify structural integrity and detect defects.

Custom stainless steel deep drawing is a versatile manufacturing technique that leverages the inherent properties of stainless steel to produce durable, precise, and aesthetically pleasing components for a wide range of industries and applications.