Conductor Pulley Stringing Blocks: Essential Tools for Power Line Installation

2025-04-22

Conductor pulley stringing blocks are essential tools used in the construction and maintenance of overhead power lines. These specialized devices are designed to assist in the installation of conductors, which carry electricity across vast distances. The primary function of a conductor pulley stringing block is to support and guide the conductor as it is pulled across the transmission line, ensuring smooth movement and preventing any damage to the conductor during the installation process.

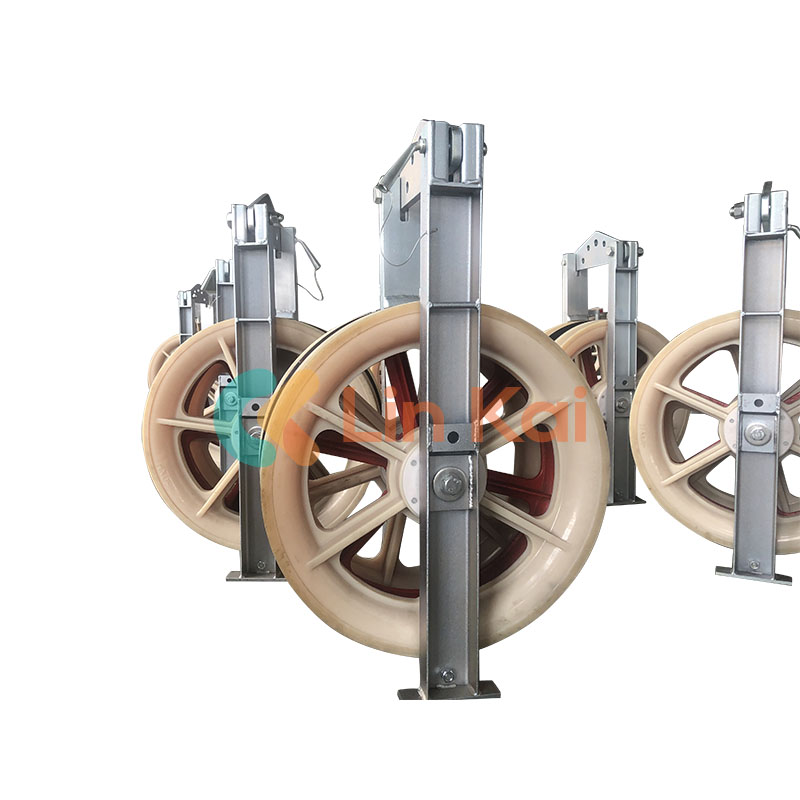

The design of a conductor pulley stringing block is typically robust and built to withstand the harsh conditions often encountered on construction sites. These blocks are made from durable materials such as high-strength steel or aluminum, and they feature precision-engineered pulleys that are capable of withstanding the significant tension exerted on the conductor during stringing. The pulleys themselves are usually lined with a smooth surface to minimize friction and prevent any abrasion on the conductor, which can lead to wear and tear over time.

One of the key advantages of using conductor pulley stringing blocks is their ability to handle heavy-duty loads. When installing power lines, especially those that span long distances, the tension on the conductors can be immense. Conductor pulley blocks help distribute this load evenly, reducing the risk of damage to both the conductor and the installation equipment. These blocks can be used in a variety of settings, from the installation of new power lines to the maintenance and upgrading of existing infrastructure.

Another important feature of conductor pulley stringing blocks is their versatility. They come in a range of sizes and configurations, allowing them to be adapted to different types of power lines, whether for low-voltage residential lines or high-voltage transmission systems. Some blocks are designed with a swivel mechanism, which allows for easy rotation during stringing, ensuring that the conductor is properly aligned and preventing any twisting or tangling.

The use of conductor pulley stringing blocks not only improves the efficiency of the stringing process but also enhances safety. By ensuring that the conductor moves smoothly through the pulley system, the blocks reduce the likelihood of sudden jerks or snags that could potentially cause accidents or damage to equipment. Their robust construction also ensures that they can withstand the heavy wear and tear of construction sites, providing reliable service for years.

In addition to their functional benefits, conductor pulley stringing blocks contribute to the overall speed and cost-effectiveness of power line installation. By facilitating the efficient and smooth movement of conductors, these blocks help minimize delays and reduce the time required to complete the installation process. This can significantly lower labor costs and improve the overall timeline for the project.

Overall, conductor pulley stringing blocks are indispensable tools in the installation and maintenance of power lines. Their durability, versatility, and ability to ensure smooth conductor movement make them a vital component of any power line construction project.