Characteristics of Marine Power Wire

2024-06-27

Marine power wire refers to electrical wiring specifically designed and rated for use in marine environments. Marine applications require wiring that can withstand harsh conditions such as saltwater exposure, moisture, and corrosion, which can quickly degrade standard electrical wiring. Here are the key characteristics and considerations for marine power wire:

Characteristics of Marine Power Wire:

1. Insulation and Jacketing:

- Waterproof and Resistant Materials: Marine wires typically feature insulation and jacketing made from materials that are resistant to water, oil, chemicals, and UV radiation.

- Cross-Linked Polyethylene (XLPE): Commonly used for insulation due to its high resistance to abrasion, moisture, and heat.

- Polyvinyl Chloride (PVC): Provides additional protection and flexibility in marine environments.

2. Corrosion Resistance:

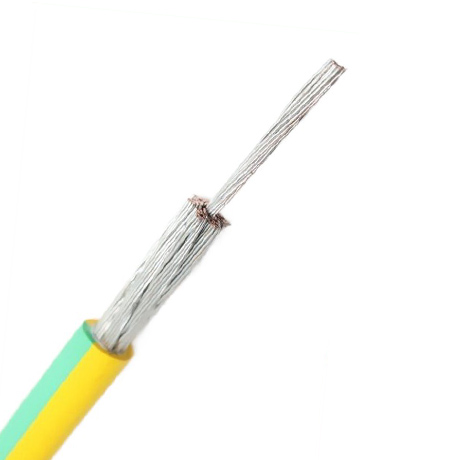

- Tinned Copper Conductors: Copper conductors are coated with tin to prevent corrosion in saltwater environments.

- Strand Construction: Stranded conductors are preferred over solid conductors as they offer better flexibility and resistance to fatigue.

3. Temperature Rating:

- High Temperature Tolerance: Marine wires are designed to withstand high temperatures, ensuring reliable performance in engine compartments and other heat-prone areas.

4. Abrasion Resistance:

- Durable Jacketing: The outer jacket is designed to resist abrasion from rough surfaces and harsh marine conditions.

5. Color Coding:

- Standardized Colors: Follows industry standards for color coding to facilitate easy identification and installation.

6. Compliance and Standards:

- Marine Grade Certification: Wires may be labeled as marine grade and comply with standards such as ABYC (American Boat and Yacht Council) and UL (Underwriters Laboratories).

Uses of Marine Power Wire:

- Boats and Yachts: Used for electrical systems, including powering lights, navigation equipment, pumps, and engines.

- Recreational Vehicles (RVs): Suitable for wiring in RVs and campers where exposure to outdoor elements is common.

- Dockside Equipment: Wiring for electrical connections on docks and marinas, including shore power and lighting.

Installation and Maintenance:

- Proper Installation: Ensure marine wires are installed according to manufacturer guidelines, including proper routing and securing to prevent chafing and damage.

- Periodic Inspection: Regularly inspect wiring for signs of wear, corrosion, or damage, especially in high-moisture areas.

- Replacement: Replace any wiring that shows signs of deterioration to maintain electrical safety and reliability.

Safety Considerations:

- Electrical Safety: Follow safety precautions when working with electrical systems to prevent shock and fire hazards.

- Waterproof Connections: Use marine-grade connectors and junction boxes to ensure watertight connections and prevent moisture ingress.

Choosing the right marine power wire ensures reliable electrical performance and safety in marine environments, where exposure to moisture, saltwater, and other harsh conditions is prevalent.