Automatic Folder Gluer Machines: Streamlining Packaging with Speed and Precision

2025-06-04

In today’s fast-paced packaging industry, efficiency, accuracy, and scalability are key. Whether you're producing folding cartons for cosmetics, pharmaceuticals, or consumer goods, investing in an Automatic Folder Gluer can be a game-changer for your production line.

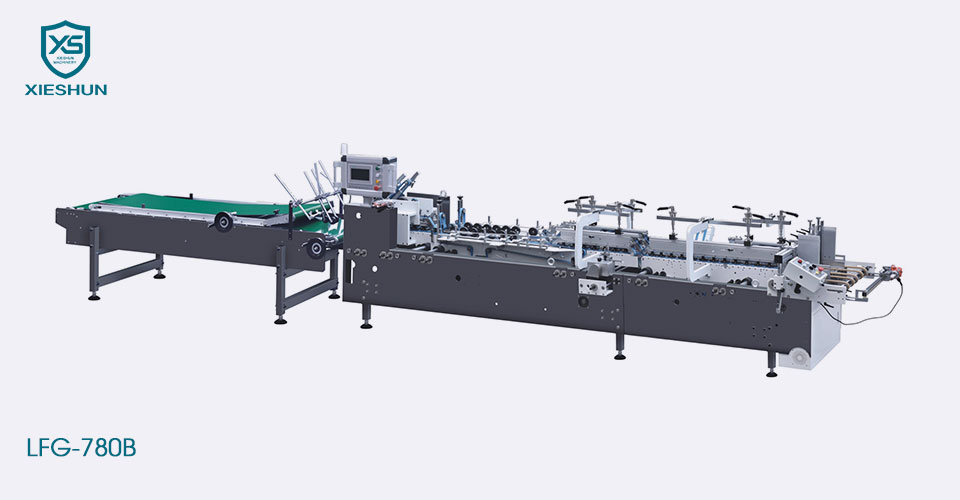

These high-speed machines are designed to fold and glue flat box blanks into finished cartons, offering a seamless combination of automation, consistency, and speed. Let’s explore what makes the automatic folder gluer essential for modern packaging operations.

What is an Automatic Folder Gluer?

An Automatic Folder Gluer is a specialized piece of finishing equipment used in packaging production. It takes pre-die-cut paperboard or cardboard blanks, folds them into shape, applies adhesive, and delivers ready-to-pack cartons — all in a continuous process.

Unlike manual or semi-automatic methods, automatic gluers handle high volumes with minimal human intervention, ensuring uniform results and reduced production costs.

Key Features of Automatic Folder Gluers

High-Speed Operation – Speeds can reach up to 400 meters per minute, depending on the machine.

Precision Folding & Gluing – Ensures perfect alignment and bonding for all box types.

Modular Design – Easily adaptable to various box styles: straight-line, crash-lock bottom, 4-corner, 6-corner, etc.

Touchscreen Controls – User-friendly interfaces for quick setup and real-time monitoring.

Automated Feeder & Delivery Systems – For smooth material handling from start to finish.

Types of Boxes an Automatic Folder Gluer Can Produce

Straight-line Boxes

Lock Bottom Boxes (Crash-lock)

4-Corner and 6-Corner Boxes

Double Wall Cartons

Specialty and Custom Folding Cartons

This versatility makes automatic folder gluers ideal for industries like food & beverage, cosmetics, electronics, pharma, and more.

Benefits of Using an Automatic Folder Gluer

1. Increased Production Efficiency

With automated feeding, folding, gluing, and stacking, you can produce thousands of cartons per hour.

2. Consistent Quality

Minimizes human error and ensures every box is folded and glued to exact specifications.

3. Reduced Labor Costs

One or two operators can manage the entire machine, significantly lowering manual labor requirements.

4. Improved Workflow Integration

Many machines can be integrated with die cutters and packing systems for a continuous production line.

5. Eco-Friendly Adhesive Application

Modern folder gluers are designed to use hot melt or cold glue systems efficiently with minimal waste.

Key Considerations When Choosing a Folder Gluer

Production volume and speed requirements

Types and sizes of cartons to be produced

Space availability on your factory floor

Operator training and ease of use

Compatibility with your existing equipment

It’s also important to consider after-sales service and technical support, as ongoing maintenance is essential for maximum uptime.

Final Thoughts

As demand for high-quality, fast-turnaround packaging grows, automatic folder gluers have become indispensable assets in the printing and packaging industries. They not only boost output and reduce costs but also elevate your product presentation with perfectly formed cartons.