Key aspects related to 5-axis CNC machining parts

2023-10-18

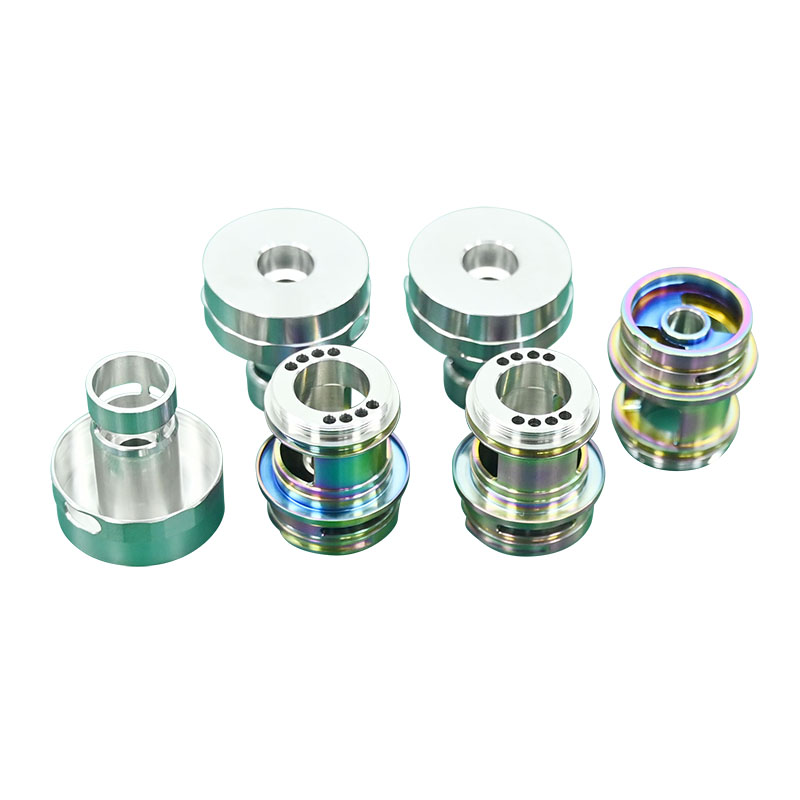

5-axis CNC machining is an advanced machining process that allows for the production of complex and intricate parts with greater precision and flexibility compared to traditional 3-axis machining. In 5-axis CNC machining, the cutting tool can move along five different axes simultaneously, enabling it to reach and machine surfaces from various angles. This capability is particularly valuable for manufacturing parts with intricate geometries and features. Here are some key aspects related to 5-axis CNC machining parts:

1. Increased Complexity: 5-axis CNC machining provides greater freedom in part design. It can produce parts with complex three-dimensional shapes, undercuts, and contours that would be challenging or impossible to achieve with traditional machining methods.

2. Improved Precision: The simultaneous movement of the cutting tool along five axes enhances precision, resulting in tighter tolerances and better surface finishes. This is especially important for industries where precision is critical, such as aerospace and medical.

3. Reduced Setups: 5-axis machines can often complete a part in a single setup, reducing the need for multiple fixturing and alignments. This not only saves time but also minimizes errors associated with part repositioning.

4. Shorter Lead Times: The ability to create complex parts in one setup can significantly reduce production lead times, making 5-axis CNC machining a competitive option for rapid prototyping and quick-turn manufacturing.

5. Versatility: 5-axis machining centers can work with a wide range of materials, including metals (like aluminum, titanium, and stainless steel), plastics, composites, and even certain ceramics. This versatility makes it suitable for various industries.

6. Optimal Tool Angles: 5-axis machines can access challenging areas of a part without repositioning the workpiece, allowing for optimal tool angles and minimizing tool deflection.

7. Reduced Waste: The enhanced precision and flexibility of 5-axis machining often result in less material waste, making it a more environmentally friendly option.

8. Industries and Applications: 5-axis CNC machining is commonly used in aerospace for complex aircraft components, in the automotive industry for engine parts and molds, in the medical field for orthopedic implants, and in the mold and die industry, among others.

9. Programming Complexity: Programming 5-axis CNC machines can be more complex than programming 3-axis machines due to the need to define toolpaths for multiple axes simultaneously. Advanced CAD/CAM software is often used to generate these toolpaths.

10. Quality Control: Quality control and inspection are crucial in 5-axis machining to ensure that the complex geometries and tight tolerances are met consistently.

Overall, 5-axis CNC machining is a powerful manufacturing technology that offers greater design flexibility, precision, and efficiency, making it suitable for producing parts used in demanding industries with complex requirements.