Non-Rising Stem Gate Valve: Essential Guide for Industrial Applications

2025-12-30

In the complex world of industrial fluid control, the choice of valves can make or break your system's efficiency. Among these critical components, the non-rising stem gate valve stands out for its durability and performance. But what truly sets it apart in demanding applications? This essential guide dives deep into the mechanics, applications, and best practices for these valves. Whether you're a seasoned engineer or new to the field, you'll discover why DRIFCO remains a trusted name in valve technology, offering solutions that keep industries running seamlessly. Get ready to explore how this specialized valve can elevate your operations.

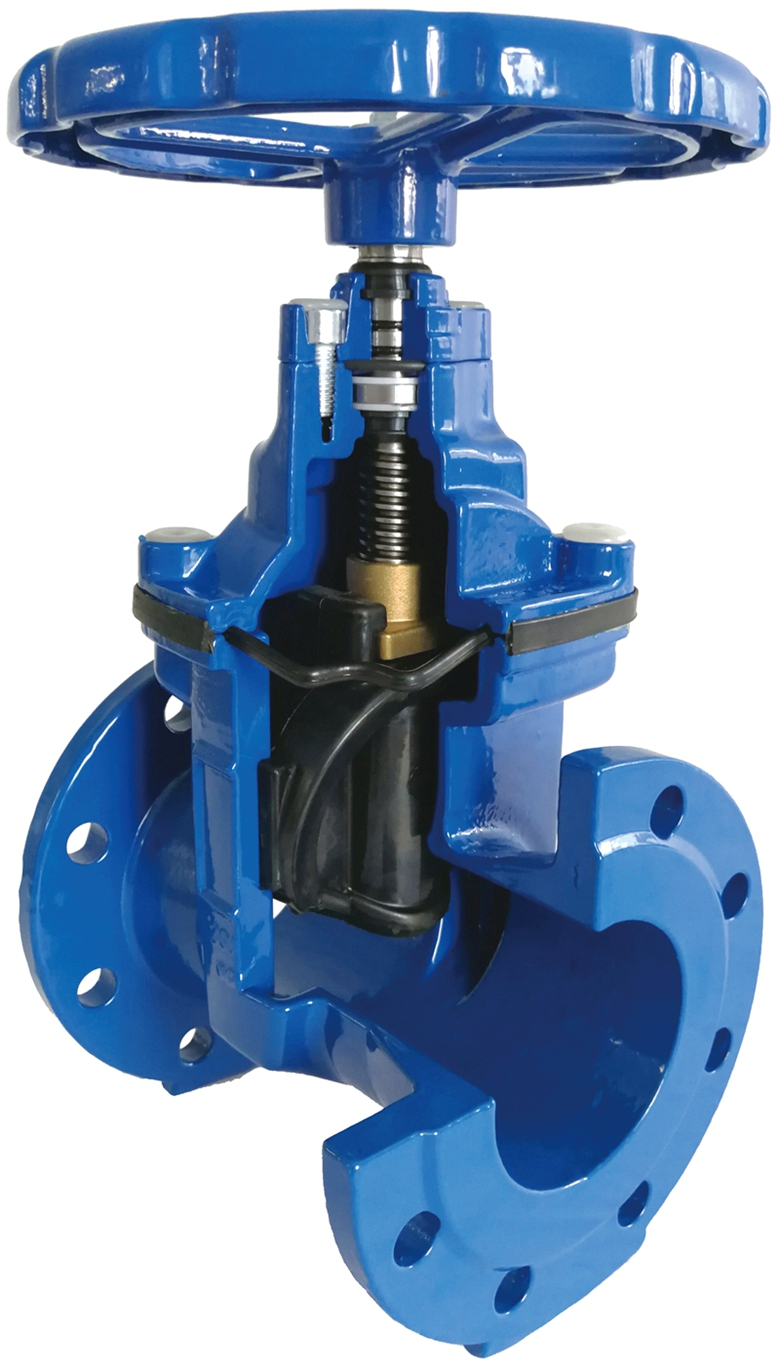

Understanding the Design and Operation of Non-Rising Stem Gate Valves

Non-rising stem gate valves, often called NRS valves, feature a design where the stem threads directly into the gate itself, causing the gate to move up and down without the stem emerging from the valve body. This compact arrangement is particularly advantageous in confined spaces, such as underground installations or tight piping systems, where vertical clearance is limited. Unlike rising stem valves that require extra room for the stem to extend, NRS valves maintain a consistent external profile during operation, making them a go-to choice for applications where space efficiency is critical, such as in municipal water systems or industrial process lines.

The operation of these valves hinges on a straightforward yet reliable mechanism: as the handwheel or actuator is turned, the stem rotates within a fixed position, engaging with the threaded gate to lift or lower it. This internal threading minimizes exposure to external contaminants, reducing wear and maintenance needs over time. However, it's important to note that because the stem doesn't rise, visual confirmation of the valve's open or closed state isn't as intuitive—operators often rely on position indicators or feel for resistance. This quiet efficiency makes NRS valves a staple in settings like fire protection systems or oil and gas pipelines, where durability and low-profile installation are prized.

In practice, the design's resilience translates to fewer operational hiccups; for instance, in harsh environments with high vibration or corrosive elements, the enclosed stem mechanism offers added protection against damage. Despite their robustness, regular lubrication of the stem threads is recommended to ensure smooth motion and prevent seizing. By balancing space-saving benefits with dependable performance, non-rising stem gate valves carve out a niche where traditional valve types might fall short, proving that sometimes the most effective solutions are those that operate quietly out of sight.

Key Advantages and Applications in Industrial Settings

Industrial settings often benefit significantly from technologies that enhance operational efficiency and reduce downtime. These solutions offer key advantages such as streamlined workflows and cost savings, making them indispensable in competitive markets. For instance, automated systems can optimize production lines, leading to faster turnaround times and improved resource management. This adaptability allows businesses to respond more swiftly to market demands and maintain a competitive edge.

In applications across various sectors, these technologies demonstrate versatility in addressing specific industrial challenges. From manufacturing plants to logistics hubs, they enable precise control and monitoring of processes, enhancing safety and reliability. For example, in heavy machinery environments, integration of advanced sensors can predict maintenance needs, preventing costly breakdowns and ensuring continuous operation. Such applications highlight how tailored innovations drive tangible improvements in day-to-day operations.

Moreover, the integration of these tools fosters collaboration and data-driven decision-making within industrial teams. By providing real-time insights and analytics, they empower workers to make informed choices, boosting overall productivity. In sectors like energy or construction, this translates to better project outcomes and enhanced compliance with regulatory standards. Ultimately, embracing these advantages leads to a more resilient and forward-thinking industrial landscape.

Material Selection and Corrosion Resistance Features

When it comes to choosing materials for industrial applications, durability often hinges on how well they can withstand environmental challenges like moisture, chemicals, and extreme temperatures. This is where corrosion resistance plays a pivotal role, guiding engineers toward options like stainless steel, aluminum alloys, and specialized coatings that offer long-term performance without frequent maintenance. By prioritizing materials with proven resistance to oxidation and chemical attacks, projects can achieve cost savings and enhanced reliability over their lifespan.

One standout approach involves tailoring material selection to specific operating conditions, such as selecting titanium for marine environments where saltwater exposure is constant, or using fiber-reinforced polymers in chemical processing plants. This customization not only boosts corrosion resistance but also optimizes weight and structural integrity, making it a strategic choice for industries ranging from aerospace to renewable energy. It's about finding that sweet spot where material properties align perfectly with real-world demands.

Innovations in this field have led to advanced alloys and surface treatments that push the boundaries of what's possible, like nano-coatings that provide nearly invisible shields against rust or self-healing materials that repair minor damage autonomously. These features allow for lighter, more efficient designs while reducing environmental impact through less waste and energy consumption. Ultimately, focusing on corrosion resistance isn't just about preventing decay; it's a forward-thinking strategy that drives sustainability and operational excellence in modern manufacturing.

Installation Best Practices and Maintenance Tips

Getting your setup right from the start can save you a ton of headaches down the line. First off, always double-check that you've got the correct tools and compatible parts before you begin—nothing's more frustrating than hitting a snag halfway through because something doesn't fit. Make sure your workspace is clean and organized; clutter can lead to lost pieces or accidental damage. Take it slow, follow the instructions step by step, and don't hesitate to reach out to customer support if you're unsure about any step. A little extra time now means fewer problems later.

Once everything's in place, establishing a routine maintenance schedule is key to keeping things running smoothly. Instead of waiting for something to break, set reminders to inspect critical components regularly, like checking for wear and tear or tightening any loose connections. Keep a log of any adjustments or replacements you make; this not only helps track the system's health but also makes troubleshooting much easier if issues arise. Simple habits, like cleaning off dust buildup or lubricating moving parts, can significantly extend the lifespan of your equipment and improve overall performance.

Beyond the basics, consider how environmental factors might affect your setup. For instance, if it's in a humid area, adding moisture control measures can prevent corrosion. Also, stay updated on any software or firmware updates that might enhance functionality or patch security vulnerabilities—just be sure to back up your data before making changes. Sharing your experiences in online forums or with friends can uncover handy tips you might not have thought of, turning maintenance into a collaborative effort rather than a chore.

Comparing Non-Rising Stem Valves to Other Valve Types

When it comes to valve selection, one key factor is the stem design, which significantly impacts installation, operation, and maintenance. Non-rising stem valves, such as those used in gate or globe styles, keep the stem stationary while the gate or disc moves internally. This design is particularly beneficial in confined spaces where vertical clearance is limited, as it eliminates the need for extra headroom typically required by rising stem models. In contrast, rising stem valves have stems that move upward as the valve opens, which can be advantageous for visual indication of valve position but may pose challenges in tight quarters.

Another point of comparison lies in durability and wear. Non-rising stem valves often expose the stem threads to the process fluid, which can lead to corrosion or fouling over time, potentially affecting smooth operation. On the other hand, other types like ball or butterfly valves might offer simpler mechanisms with fewer moving parts, reducing maintenance needs but sometimes at the cost of precise flow control. For instance, ball valves are great for quick on/off applications, but they might not provide the fine throttling capability that some non-rising stem globe valves can achieve.

From a practical standpoint, non-rising stem valves are commonly found in underground or submerged applications, such as water distribution systems, where space constraints and environmental factors are critical. Comparing them to alternatives like plug valves or diaphragm valves, each has its niche: plug valves excel in handling slurries, while diaphragm valves are ideal for corrosive fluids. Ultimately, the choice depends on specific requirements like pressure ratings, fluid compatibility, and operational frequency, making it essential to weigh these trade-offs rather than opting for a one-size-fits-all solution.

Troubleshooting Common Issues and Enhancing Longevity

When it comes to keeping your devices in top shape, a few simple habits can make all the difference. Start by regularly checking for software updates, as ignoring these can lead to glitches and security risks. Dive into the settings menu to ensure automatic updates are enabled, and clear out any lingering caches that might slow things down. Over time, dust buildup can hinder performance, so a quick clean with compressed air can prevent overheating and unexpected shutdowns. I've seen many systems go from sluggish to smooth just by staying on top of these basics.

Beyond routine maintenance, be proactive in spotting early warning signs. If your hardware feels unusually warm or makes strange noises, that's a clear signal to investigate before things escalate. Keep an eye on battery health—avoid leaving it plugged in constantly or draining it completely to extend its life. For mechanical parts like fans or hinges, a gentle wipe-down every few months prevents wear and tear, ensuring they move smoothly for years. By addressing these issues promptly, you'll avoid costly repairs and keep everything running like new.

For long-term durability, think about your usage patterns and adapt accordingly. Store devices in cool, dry places away from direct sunlight to prevent material degradation. Rotate between multiple gadgets if possible to reduce strain on any single one, and invest in quality accessories like surge protectors to shield against power surges. Remember, a little care upfront can double the lifespan of your equipment, saving you money and hassle down the line.

FAQ

A non-rising stem gate valve features a stem that does not move upward when opening or closing, making it ideal for tight spaces where vertical clearance is limited.

It operates by rotating the handwheel to move the gate up or down within the valve body, with the stem threads engaging inside the bonnet to control flow without external stem extension.

These valves are commonly used in water treatment plants, oil and gas pipelines, and HVAC systems due to their compact design and reliable shut-off capabilities.

They save space by not requiring extra vertical room, reduce maintenance needs as the stem is protected inside, and are easier to install in confined areas.

Regular lubrication of the stem threads, inspection for wear or corrosion, and ensuring proper alignment during operation help extend valve lifespan and prevent leaks.

Yes, they can be harder to visually confirm open/closed status compared to rising stem valves, and internal stem damage may be more difficult to detect without disassembly.

Conclusion

Non-rising stem gate valves are indispensable components in industrial systems, known for their unique design where the stem does not ascend during operation, making them ideal for space-constrained environments. Understanding their design reveals how a threaded mechanism within the valve body allows precise control without height adjustments, enhancing operational safety. Key advantages include robust sealing capabilities and suitability for high-pressure applications, widely used in water treatment, oil and gas, and chemical processing. Material selection, such as stainless steel or bronze, ensures corrosion resistance in harsh conditions, while installation best practices emphasize proper alignment and gasket integrity for optimal performance.

Maintenance tips focus on regular lubrication and inspection to prevent issues like stem binding or leaks, with troubleshooting addressing common problems like wear or misalignment. Comparing these valves to rising stem or ball valves highlights their compactness and durability, though they may require more frequent upkeep in abrasive settings. By integrating these aspects, non-rising stem gate valves offer reliability and efficiency, ensuring longevity and minimal downtime in various industrial applications, supported by practical guidelines for effective use and problem-solving.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com