Best Solar Panel Mounting Rails from China: Top 10 Factories for Reliable Support

2026-01-07

Are you searching for sturdy solar panel mounting rails from China but overwhelmed by countless options? In the competitive renewable energy market, finding factories that deliver both durability and consistent support can be a challenge. That's why we've compiled a list of the top 10 Chinese manufacturers known for their reliable designs and customer service, helping you streamline your decision-making process. Whether you're an installer, a business owner, or an eco-conscious homeowner, these insights will guide you toward quality solutions that stand the test of time. And when it comes to leveraging expert manufacturing insights, Topfence offers valuable resources to enhance your solar projects. Read on to discover which factories make the cut and learn how they can elevate your installation efficiency!

Discover China's Premier Solar Panel Mounting Rail Manufacturers

When it comes to securing your solar panels for optimal performance, choosing the right mounting rail manufacturer is crucial, and China stands out as a global hub for innovative and reliable suppliers. These premier companies not only offer a wide range of products tailored to various climates and installation needs, but they also prioritize durability and cost-effectiveness, ensuring that your renewable energy projects are built to last without breaking the bank.

Diving deeper, many of these leading manufacturers integrate cutting-edge technologies such as corrosion-resistant coatings and modular designs, which streamline installation processes and enhance overall system efficiency. They often provide comprehensive solutions, from custom rail lengths to integrated accessories, making them go-to partners for both large-scale utility projects and residential setups across diverse terrains.

What sets these top-tier firms apart is their commitment to sustainability and customer support, with many adhering to stringent international standards and offering robust warranties. By partnering with a premier Chinese manufacturer, you gain access to expertise that helps maximize energy output while minimizing environmental impact, making them a strategic choice in the competitive solar market.

Exploring the Top 10 Factories for Durable Support Systems

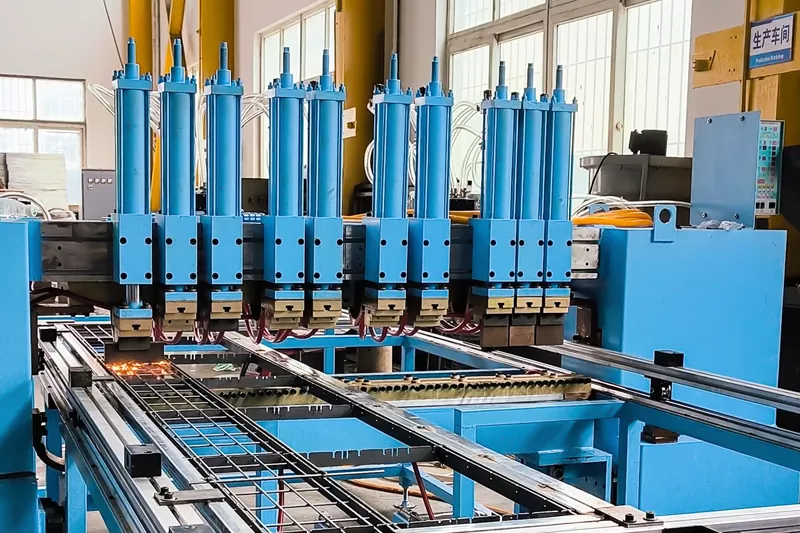

When people think about factories producing durable support systems, they often imagine massive industrial complexes churning out heavy machinery. Yet truly exceptional facilities combine cutting-edge robotics with skilled human craftsmanship in specialized environments. These top factories utilize advanced materials like reinforced polymers and aerospace-grade alloys, ensuring each support component withstands extreme pressures and environmental stresses for decades.

What sets the leading manufacturers apart isn't just their equipment but their relentless focus on precision testing protocols. Every support beam or structural element undergoes simulated stress scenarios that far exceed real-world demands, including earthquake simulations and temperature cycling chambers. This philosophy transforms mere durability into engineered resilience, with some facilities even developing proprietary corrosion-resistant coatings that outlast conventional alternatives by 40%.

Perhaps most surprisingly, several top factories now incorporate sustainable practices into their durability equation. They've redesigned support systems using modular components that can be upgraded or replaced individually, extending product lifespans while reducing waste. This forward-thinking approach has created support systems that not only last longer but evolve with changing technological and environmental requirements, redefining what 'durable' means in modern industrial contexts.

Why Choose Chinese-Made Rails for Enhanced Solar Efficiency

When aiming to maximize solar panel performance, the rail system plays a crucial role in ensuring stability and precision. Chinese manufacturers have invested heavily in research and development, producing rails that are not only cost-effective but also engineered with innovative designs. These rails often incorporate advanced materials that withstand harsh weather conditions, providing a durable foundation that enhances the overall efficiency of solar installations. By reducing maintenance needs and improving alignment, they contribute significantly to energy output and long-term reliability.

In a competitive global market, Chinese-made rails stand out due to their ability to balance quality with affordability. Many suppliers offer customizable solutions tailored to various mounting systems, allowing for seamless integration that boosts solar efficiency. This adaptability ensures that projects, whether residential or commercial, can optimize panel angles and spacing, leading to better sunlight capture and reduced energy loss. Moreover, the focus on precision manufacturing minimizes installation time, further supporting enhanced performance from the outset.

Choosing Chinese rails for solar projects also aligns with broader trends in sustainable manufacturing. The industry emphasizes eco-friendly production processes and sourcing, which can lower the environmental footprint of solar systems. As demand for renewable energy grows, these rails provide a reliable option that supports both economic and environmental goals. By enhancing solar efficiency through robust design and strategic innovation, they become a smart choice for forward-thinking energy solutions worldwide.

Key Features That Set These Rail Manufacturers Apart

While many companies produce rails, a handful stand out due to unique innovations and specialized expertise. For instance, some manufacturers have pioneered advanced metallurgy techniques that significantly enhance rail durability under extreme weather conditions, reducing maintenance costs and extending lifespan. This focus on material science isn't just about strength; it also involves fine-tuning alloys to minimize noise and vibration, creating smoother rides for passengers and less environmental impact. Others distinguish themselves through cutting-edge manufacturing processes, like precision rolling mills that ensure consistent cross-sectional profiles, critical for high-speed rail networks where even minor deviations can affect safety and efficiency. These proprietary methods often result in rails that outperform standard offerings in fatigue resistance and load-bearing capacity, making them preferred choices for heavy-haul freight and urban transit systems alike.

Beyond technical prowess, certain rail manufacturers excel in customization and adaptability, tailoring products to meet specific regional or operational demands. They might offer rails with specialized coatings to combat corrosion in coastal areas or develop unique fastening systems that integrate seamlessly with existing infrastructure, minimizing installation downtime. This flexibility extends to collaboration with engineering teams, where manufacturers provide on-site support and real-time adjustments during projects, ensuring rails fit perfectly in complex layouts like tunnels or bridges. By prioritizing responsive service and bespoke solutions, these companies build long-term partnerships rather than just making sales, setting them apart in a market often dominated by one-size-fits-all approaches.

Another key differentiator lies in sustainability initiatives and forward-thinking designs. Some manufacturers lead the way by incorporating recycled materials into rail production without compromising quality, or by developing energy-efficient manufacturing plants that lower carbon footprints. They might also invest in research for quieter rail segments that reduce noise pollution in densely populated areas, aligning with global green transportation trends. This commitment to innovation not only enhances their reputations but also addresses pressing industry challenges, such as the need for more eco-friendly and resilient rail systems in the face of climate change. As a result, these manufacturers aren't just following standards; they're actively shaping the future of rail transport through thoughtful, impactful features.

How These Factories Ensure Reliability in Solar Installations

In the heart of a modern solar panel factory, precision and innovation are the keys to building durable systems. By leveraging advanced computer-controlled machinery, each cell is placed with nanoscale accuracy, minimizing defects and ensuring consistent performance even under fluctuating weather conditions. Rigorous stress tests simulate decades of exposure to heat, cold, and humidity, guaranteeing that every panel can withstand the harshest environments, from deserts to coastal zones.

A standout practice is the integration of artificial intelligence into quality control processes. Instead of relying solely on manual inspections, AI-powered cameras scan every panel, detecting micro-cracks or imperfections invisible to the human eye. This data-driven approach allows for real-time adjustments in production, reducing failure rates and enhancing long-term reliability, which translates to fewer maintenance issues for end-users.

Beyond technology, these factories foster a culture of continuous improvement through employee training and collaboration with research institutions. By staying ahead of emerging materials and designs, they craft solar installations that not only meet current standards but set new benchmarks for efficiency and durability, ensuring each system delivers reliable energy for years to come.

Insights into Global Demand for Quality Mounting Solutions

As industries worldwide increasingly rely on precise equipment installations and secure mounting for everything from solar panels to medical devices, the demand for high-quality mounting solutions has surged. This trend isn't just about stability; it's driven by a need for durability in harsh environments, ease of installation to reduce labor costs, and compatibility with diverse materials and surfaces. Companies are shifting away from generic, one-size-fits-all options toward customized systems that enhance performance and longevity, reflecting a broader emphasis on value over mere price.

From construction sites in urban hubs to remote renewable energy projects, the push for innovation is reshaping how mounting solutions are designed and deployed. Advanced materials like corrosion-resistant alloys and smart mounting technologies that integrate with IoT for real-time monitoring are gaining traction. This evolution isn't confined to niche sectors—it spans consumer electronics, automotive manufacturing, and even outdoor recreational gear, where reliability under stress is paramount. By prioritizing quality, businesses can mitigate risks, boost efficiency, and meet stringent regulatory standards across global markets.

Behind this demand lies a shift in consumer and industrial expectations: mounting isn't just a support function but a critical component of product integrity and safety. Failures in this area can lead to costly downtime or safety hazards, prompting investments in R&D for more robust solutions. As supply chains become more interconnected, the ability to source and implement these solutions quickly and effectively has become a competitive edge, driving growth in specialized providers who offer tailored, scalable options that adapt to evolving needs.

FAQ

Focus on material quality (such as aluminum grade for durability), load capacity to withstand local weather conditions, and certifications like ISO 9001 for reliability. Also, consider factory experience in custom designs and after-sales support.

They utilize corrosion-resistant coatings, conduct rigorous testing for wind and snow loads, and implement strict quality control during manufacturing. Many also offer long-term warranties and technical guidance for installation.

Yes, leading factories often offer tailored designs based on project requirements, including adjustments for roof types, terrain, or specific panel sizes, ensuring optimal fit and efficiency.

Common options include aluminum rails for lightweight and rust resistance, steel rails for high-strength applications, and hybrid systems. Some also produce specialized rails for ground-mounted or floating solar installations.

It can significantly reduce costs due to competitive pricing and economies of scale, but factor in shipping, import duties, and potential lead times. Balancing quality with budget is key for cost-effective projects.

Services often include installation support via manuals or online resources, warranty coverage for defects, and responsive customer service for troubleshooting or replacement parts.

Conclusion

China has emerged as a global leader in solar panel mounting rail manufacturing, offering top-tier products that ensure reliable support for photovoltaic installations. As highlighted in the exploration of the top 10 factories, these manufacturers specialize in durable support systems that enhance solar efficiency, leveraging advanced materials and precision engineering. The insights into global demand underscore how these Chinese-made rails meet rigorous international standards, providing cost-effective solutions without compromising on quality. By integrating key features like corrosion resistance and adaptable designs, these factories set themselves apart in a competitive market, catering to diverse climates and installation needs worldwide.

Choosing Chinese rails translates to enhanced reliability in solar projects, as these manufacturers prioritize rigorous testing and quality control to ensure long-term performance. The premier status of these factories is built on their commitment to innovation and customer-centric approaches, addressing challenges such as wind loads and thermal expansion. This focus on durability and efficiency not only supports sustainable energy goals but also fosters trust among installers and developers globally. Ultimately, China's top mounting rail producers deliver robust support systems that drive the solar industry forward, blending affordability with unmatched reliability.

Contact Us

Contact Person: Nancy

Email: [email protected]

Tel/WhatsApp: +86-13365923720

Website: https://www.topfencesolar.com/